Biological Products:

Bioaugmentation products for Wastewater applications in Papermills, Refineries, Chemical, Tanneries, Municipalities, Textiles, Steel, Agriculture, Animal feedlot, Gun Powder plant, Food and Beverage- Dairy Products, Orange Juice factory, Wineries, Cookie factory, Vegetable processing plant, Meat packing, Barbecue Restaurant, Aquaculture, Ornamental Ponds for algae control, CAFO, Nursing homes, Military, Campgrounds, Universities, Regulatory agencies

Lab Services:

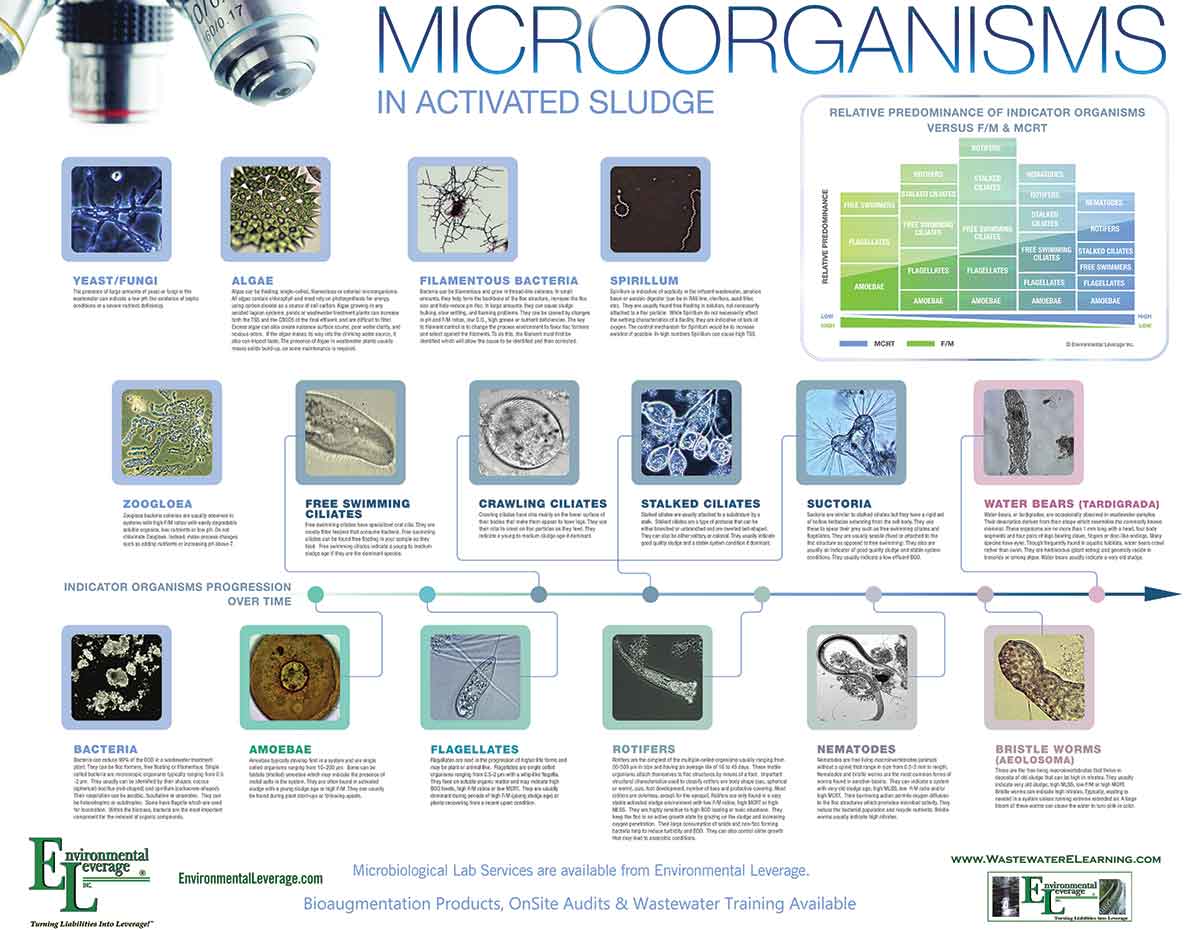

Filamentous Identification Lab Service. One reason to identify filaments is to determine the filaments characteristics and then determine the type present. If the type is found out, a root cause can usually be associated with a particular filament. If the cause is known, then a correction can be made to alleviate problems. Chlorination is only a quick fix. Without process changes, filaments will grow back after chlorination. Wastewater Biomass Analyses and Cooling Tower Analyses also available

Training Materials:

Training is an integral part of any job. Not everyone is at the same level of training. Many people want beginning concepts and basics. Some need technical information or troubleshooting. Some want equipment, technology or process information. We have developed a full set of Basic training, Advanced training, Filamentous Identification the Easy Way as well as custom training CD's Manuals. We also provide hands-on training classes and soon will have an Online "E-University".

Audits and Consulting:

At Environmental Leverage® Inc., we have a team of experienced individuals who come into your plant with a fresh pair of eyes. The system is checked from influent to effluent. System optimization, equipment efficiency and operational excellence are key components explored. Key Benefits Equipment efficiency Total Cost of Operation reductions Reliability and safety An onsite audit is conducted to examine system parameters, process controls, and current monitor and control procedures. A physical walk-through is conducted, process flow diagrams are examined, previous design criteria are examined and current standard operating procedures are evaluated along with data logs.

|

Case HistoriesLatest News!

What's New!

We have just added "Virtual Audits" to our capabilities. Check out our new Services. We are in the process of developing new courses for our ""Online E-University" in order to meet the needs of our global customers that cannot travel to our public classes.Visit our new website www.WastewaterElearning.com/Elearning PapermillWe were asked over a year ago to come in and troubleshoot for a papermill with a once through lagoon. We made some process recommendation, gave some training and revised their current bioaugmentation program. The final effluent had the best BOD in the history of the plant. But, since the plant was on a "sole source " agreement with a major supplier of all their chemicals, they were forced to go back to their original supplier for biological products. Well, after just 6 months, the plants is back on our products and program. The results could not even come close on their program!

While we believe some of our products are specially formulated and are very good, the major thing we believe is important is the training, consulting, analyses and support that we have to offer. But the real proof is in the final BOD number! Check to see how we compare. . . .

BOD final permit limits are 25 and TSS numbers are 30 ppm. We consistently hit close to 5 ppm BOD once the program was up and running! Very good for a papermill! Even the cold weather months with a normal slowdown in activity, the BOD was still on the mark!

TSS is more a function of the primaries and they just installed an umber of new thickeners, a new sludge recycle pump during various points in this trial, so TSS was not really an issue between both companies, but BOD was the real driver! More data on this case history!

More Pulp and Papermill Case Histories

Case History : Municipal Foaming and Nocardia

We started working with a municipality that had a history of foaming

problems and Nocardia for years. They already were on a biological program.

We came in, audited the plant, made some process recommendations, changed

the program to a dual program. You can see solids build-up in the

clarifier and the scum box is filled. The photo on the right is the thick

Nocardia foam in the aeration basins. For the first time the plant has actually seen MLSS in the aeration

basins!

You can see the surface of the aeration basin, normal MLSS and the scum box

now only has a small amount of scum. This plant will have to fight grease and foaming continually until it has

an upgrade to the system, since it does not have prescreening to remove some

of the grease and solids that do come in to normal municipal systems.

Optimization of the primary, changes to the solids handling in the clarifier

and a minor adjustment to the bacterial program will help to keep the plant

running more smoothly though in the meantime! More Case Histories Fats Oils and

Grease Case histories

Pump Station

February 14th 2007 prior to treatment

February 20th 2007 after treatment This case history with such a great success is from one of our

distributors ELI HALPERIN E.H.GREEN PRODUCTS

But some plants have constantly changing influents. No matter how great

a control they have, their biomass is in constant flux. Sometimes adding a

biological product or micronutrients can help stabilize and increase the

efficiency of the biomass.

Case Histories

Collections systems and Lift stations

2

day Training Seminars - Click this line link for Training Class Schedule Biological Wastewater Treatment Training Classes

Class Instructor: Tracy Finnegan, President / Principal Consultant, Environmental Leverage®

Inc.

Bioaugmentation Benefits

- Click this line or Product picture link for Information increased BOD / TSS

Removal

|