Biological Products:Bioaugmentation products for Wastewater applications in Papermills, Refineries, Chemical, Tanneries, Municipalities, Textiles, Steel, Agriculture, Animal feedlot, Gun Powder plant, Food and Beverage- Dairy Products, Orange Juice factory, Wineries, Cookie factory, Vegetable processing plant, Meat packing, Barbecue Restaurant, Aquaculture, Ornamental Ponds for algae control, CAFO, Nursing homes, Military, Campgrounds, Universities, Regulatory agencies

Lab Services:Filamentous Identification Lab Service. One reason to identify filaments is to determine the filaments characteristics and then determine the type present. If the type is found out, a root cause can usually be associated with a particular filament. If the cause is known, then a correction can be made to alleviate problems. Chlorination is only a quick fix. Without process changes, filaments will grow back after chlorination. Wastewater Biomass Analyses and Cooling Tower Analyses also available

Training Materials:Training is an integral part of any job. Not everyone is at the same level of training. Many people want beginning concepts and basics. Some need technical information or troubleshooting. Some want equipment, technology or process information. We have developed a full set of Basic training, Advanced training, Filamentous Identification the Easy Way as well as custom training CD's Manuals. We also provide hands-on training classes and soon will have an Online "E-University".

Audits and Consulting:At Environmental Leverage® Inc., we have a team of experienced individuals who come into your plant with a fresh pair of eyes. The system is checked from influent to effluent. System optimization, equipment efficiency and operational excellence are key components explored. Key Benefits Equipment efficiency Total Cost of Operation reductions Reliability and safety An onsite audit is conducted to examine system parameters, process controls, and current monitor and control procedures. A physical walk-through is conducted, process flow diagrams are examined, previous design criteria are examined and current standard operating procedures are evaluated along with data logs.

|

I don't have Filaments at my plant!What's New!

We have just added "Virtual Audits" to our capabilities. Check out our new Services. We are in the process of developing an ""Online E-University" in order to meet the needs of our global customers that cannot travel to our public classes. Stay tuned for details and updates.

A common misnomer in many wastewater treatment plants is that unless they have filaments that are bridging and they can see them between the floc structures, they do not have filaments. In reality, internal bulking can cause more problems than slight bridging.

Well what is the difference between bulking or bridging? Bridging is when the filaments are external to the normal floc structure and cause a bridge between the floc structures. Many plants think there is only a problem when they have external filaments that are causing bulking problems. In reality there are three ways to cause bulking at a plant, internal filaments, external filaments or non-filamentous bulking- which can be caused by zooglea, fungi and in many municipalities or papermills, fiber or tissue.

What is the difference and how do they

impact the plant? Let's take a closer look at all of these scenarios.

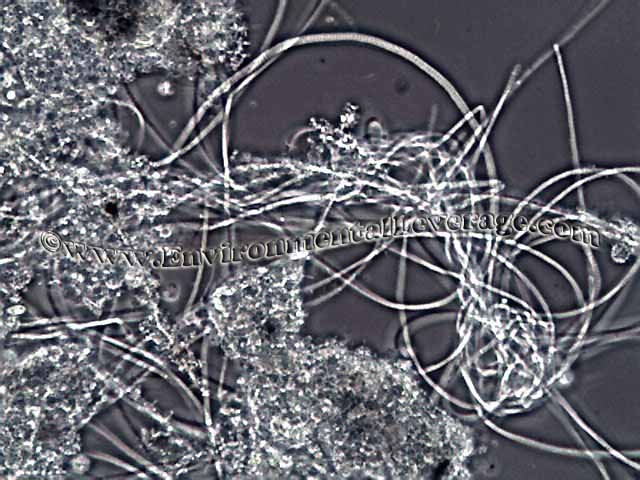

Filaments can be internal, external or free floating. Internal filaments are like a sponge. They can be hard to settle and dewater. External filaments keep the floc structures from coming together and compacting. Free-floating filaments can cause TSS problems. Zooglea and fungi can cause foaming, sliming or bulking. Let's first look at some samples from a few plants that have external bulking and what most operators think is the only case for filamentous problems. External filaments are those filaments that extend into the bulk solution and cause difficulty in settling. They form a bridge between the floc structures and make compaction difficult. They can take up large amounts of space in a clarifier or digestor or even aeration basin.

This plant on the left has abundant levels of filaments and this one on the right has excessive levels of filaments that will make it hard to settle in the clarifier, hard to dewater and increase polymer consumption and increase solids hauling costs.

This is typically what people think of when they talk about filamentous bulking. While you may think you have a large amount of bacteria when doing a settlometer, in reality, the filaments are just taking up space.

Most operators are well aware of bridging and this is usually what is

thought of for filamentous problems. But you need to check again.

Internal bulking is when the filaments are inside the floc structure and make up a backbone for the floc. In a small amount, internal filaments are a great plus. They help keep the floc together, help avoid shear and give stability to the floc. In large amounts, they can create a floc that is more like a sponge. It is very hard to dewater and compress. It can take large amounts of polymer to get the floc to settle in the clarifier. Solids can build up. Carryover or washout can occur quite easily. Polymer consumption on a belt press can increase. Solids dewatering is harder to achieve. Dryer cake solids are harder to achieve. With solids handling costs on the rise and a big part of a budget at any wastewater treatment plant, filaments can add a significant chuck to any budget.

Internal filaments are very common, often overlooked and ignored and yet many operators or supervisors of wastewater plants cannot figure out why they have too many solids, overloading or problems and high costs with solids handling.

Look closer, use stains or call your local lab or Environmental Leverage to help you with a filamentous identification or training

If you need more information on our Filamentous Identification the Easy Way Training CD or on Internet training on Filamentous bacteria, causes and controls

How are your bugs doing?

|