Biological Products:

Bioaugmentation products for Wastewater applications in Papermills, Refineries, Chemical, Tanneries, Municipalities, Textiles, Steel, Agriculture, Animal feedlot, Gun Powder plant, Food and Beverage- Dairy Products, Orange Juice factory, Wineries, Cookie factory, Vegetable processing plant, Meat packing, Barbecue Restaurant, Aquaculture, Ornamental Ponds with algae , CAFO, Nursing homes, Military, Campgrounds, Universities, Regulatory agencies, River and Lake remediation

Lab Services:

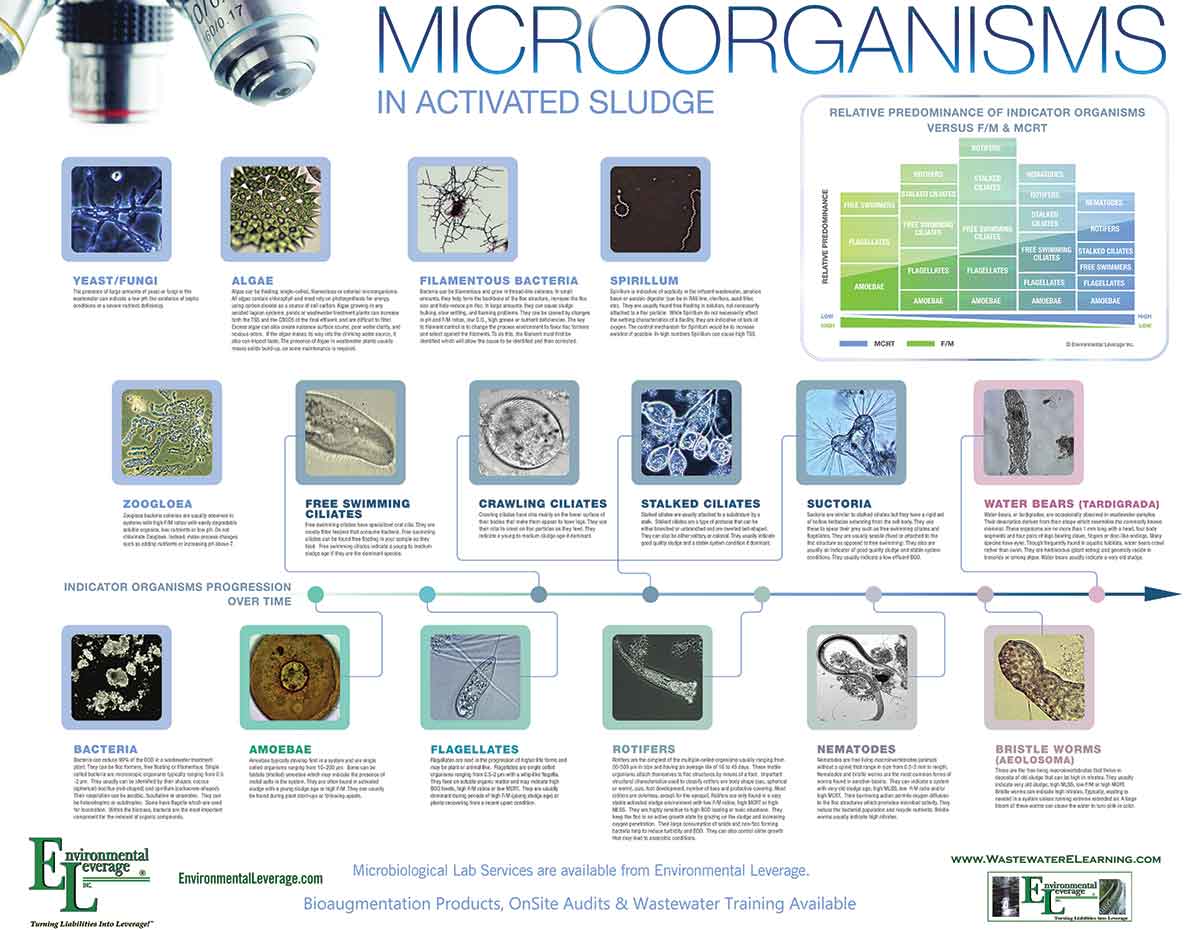

Filamentous Identification Lab Service. One reason to identify filaments is to determine the filaments characteristics and then determine the type present. If the type is found out, a root cause can usually be associated with a particular filament. If the cause is known, then a correction can be made to alleviate problems. Chlorination is only a quick fix. Without process changes, filaments will grow back after chlorination. Wastewater Biomass Analyses and Cooling Tower Analyses also available

Training Materials:

Training is an integral part of any job. Not everyone is at the same level of training. Many people want beginning concepts and basics. Some need technical information or troubleshooting. Some want equipment, technology or process information. We have developed a full set of Basic training, Advanced training, Filamentous Identification the Easy Way as well as custom training CD's Manuals. We also provide hands-on training classes and soon will have an Online "E-University".

Audits and Consulting:

At Environmental Leverage® Inc., we have a team of experienced individuals who come into your plant with a fresh pair of eyes. The system is checked from influent to effluent. System optimization, equipment efficiency and operational excellence are key components explored. Key Benefits Equipment efficiency Total Cost of Operation reductions Reliability and safety An onsite audit is conducted to examine system parameters, process controls, and current monitor and control procedures. A physical walk-through is conducted, process flow diagrams are examined, previous design criteria are examined and current standard operating procedures are evaluated along with data logs.

|

Industry TroubleshootingLatest News!

What's New!

We have just added "Virtual Audits" to our capabilities. Check out our new Services. We are in the process of developing new courses for our ""Online E-University" in order to meet the needs of our global customers that cannot travel to our public classes.Visit our new website www.WastewaterElearning.com/Elearning

Give us a call at Environmental Leverage® Inc. for an audit/consulting and we can address areas that can have beneficial reuse. Reuse audit information can also be included in your troubleshooting audit as well. Call 630-906-9791 or email us at elfenvironmental@aol.com

Paper mills The pulp and paper industry uses 84% of the energy consumed by the forest products industry. Some average benchmarks include: Solid Waste generation- .01-.26 tons per ton of product (TPT), Landfill cost-$10-20 million, Knots- reuse them or waste, wood yard waste - .02-.06 TPT, Sludge from a de-inking process has only 50% of the energy of bark, Typical Sludge generation- .02-.06 TPT, Lime mud is limited by kiln production -up to 200 tons per day. Ash generation rates are approximately 0.04 TPT from Georgia pulp mills. Pulp and Paper Mills- More information

Refineries- Petroleum refining is the most energy-intensive manufacturing industry in the United States. Refineries have numerous wastewater issues in their plants. Some plants have too much ammonia or amines in the influent and need to nitrify. Nutrient control at refineries plants can be a serious issue. Alkalinity is typically a factor often overlooked with nitrification at refineries. In the wastewater plant, not only do you need to control and nitrifiers, but also the carbonaceous bacteria need monitor and control for proper biological activity and final effluent BOD and TSS controls along side of nutrient control. Many refineries have API's or DAF's prior to the secondary treatment system with Activated Sludge or aeration basins. The more oil and scum solids that can be removed prior to the Aeration Basin, the easier the loading on the biomass in the Aeration basin. Refineries- More information

Steel Mills- Steel is one of nine energy- and waste- intensive industries that is participating with the U.S. Department of Energy's Office of Industrial Technologies in a new collaborative R&D strategy called "Industries of the Future." http://www.oit.doe.gov/steel/ . The steel industry (including iron production) is one of the largest energy consumers in the manufacturing sector and has invested more than $7 billion in environmental controls. Steel is the most recyclable and recycled material in North America, with an overall recycling rate of 68 percent. Steel Mills-More information

Many do not have waste treatment plants and instead discharge directly to a POTW. Publicly

owned treatment works (POTW) that receive food-processing wastewater with

BOD5 values greater than 250 to 300 mg/L typically will add an additional

surcharge for treatment. Small changes to the process or additions of small

levels of certain chemicals or bacterial products can lower the BOD/COD and

TSS created and significantly lower these surcharges. Check out our

bioengineering page for more information or

request

case history examples. More information

Dairies- Dairies have numerous issues to deal with-Land and Water Considerations, Nutrient Management, Odors, Common Concerns Associated with Expansion, Concentrated Animal Feeding Operations- CAFO regulations, permits and licensing, health and safety, Manure Storage and solids handling. U.S. Environmental Protection Agency (EPA) is proposing regulations that will require dairy and other producers to control and contain runoff from their land, as well as regulate type and scope of livestock operations. Production has been forced to become concentrated in fewer but larger dairies, and environmental concerns over the industry's waste products are placing increasing pressure on dairy operations. Heightened environmental concerns and need for resource conservation have caused implementation of water use permits and other possible regulatory actions in many states. These may include water intake limits, water effluent limits, permit restrictions, air quality restrictions or solids handling limitations. more on Dairies-how to treat wastewater or reduce odors

Meat processing includes slaughtering, processing, and rendering operations involving primarily cattle, hogs, and poultry. Some plants handle only one type of operation, such as meat processing, but others carry out multiple operations including rendering., smoking, canning, freezing, and sausage making.

Animal Feed lots- Odor Control and

Water clarification for final effluents or recycle are the prime goals of

these applications to help farmers. More on

concentrate Animal Feed Organizations- CAFO and some of the solutions

available

Aquaculture- Fish and Shrimp Farms

Wastewater issues " The Blue Revolution"

Aquaculture is the farming of aquatic organisms, including finfish,

shellfish (mollusks and Many

Chemical Plants have numerous

side streams that can be isolated and used elsewhere. Some examples

are waste streams that are high in pH, ammonia or phosphate that can be used

by

Municipalities-With all the new

growth in a village or city, many changes are happening that impact the

ability of the POTW to handle the incoming wastewater. High growth spurts

in new developments have not only impacted the flow rates to the wastewater

treatment plant, but the loading has increased also. Why, it should be

proportional to the changes in the houses and developments. While that

should be true, it is often not the case. Many of the old tried and true

engineering statistics calculated flow, and loading based upon population

and growth. Municipalities

have numerous areas that they have to address. Not only do they have the

normal wastewater treatment system and the many problems associated with it.

They also have to worry about the collection systems, plugged lines, grease

build-up, rainwater overflows and power outages. Solids handling is a huge

cost at many plants.

Grease and Lift Stations in Collection

Systems Operators of sewerage systems know that grease in

lift stations is a major problem. The grease obstructs floats and reduces

the life of pumps leading to SSO's and a need for frequent service.

Obstruction by grease is the most prevalent cause of force main backups and

sewage overflows, costing the industry billions of dollars annually. The

majority of sewer line blockages are caused by grease build-up as opposed to

debris.

Obviously, we cannot go into all the types of plants, side streams or

situations for process improvements or beneficial reuse that possibly could

occur here. There is a ton of information on the internet and through your

local EPA as well as Federal government sites. If you are short handed

on your own staff and would like to consider consulting from Environmental

Leverage please feel free to contact us at ELFEnvironmental@aol.com or

fill out a request sheet at

Feedback Here are some good links that may be of help http://www.epa.gov/epaoswer/non-hw/recycle/jtr/comm/index.htm Commodities Recyclable materials are bought and sold just like any other commodity.

As with other commodities, Many states have developed beneficial reuse programs and regulations

http://www.epa.gov/epaoswer/non-hw/recycle/jtr/comm/sand.htm Foundry sand primarily consists of clean, uniformly sized, high-quality

silica sand or lake sand that is bonded to form molds for ferrous and

nonferrous metal castings. The iron and steel industries account for

approximately 95 percent of foundry sand used for castings.

International and National Materials Exchanges

http://www.epa.gov/epaoswer/non-hw/recycle/jtr/comm/exchnat.htm

Pollution Prevention Opportunities Links to tons of troubleshooting newsletters

Case Histories

Wastewater Training Options The greatest equipment and the most efficient, dedicated workers can be

ineffective if they are not properly trained. At Environmental Leverage, we

have years of experience in many process areas and technical expertise on

equipment, systems and operations. Programs to optimize your system or

custom training can be tailored to increase the reliability and efficiency

of your plant.

Look

for self taught training materials and training courses below.

We have developed a full line of Training CD's and Elearning classes

for training and operator CEU's.

Elearning and General

Brochure Click for brochure Since wastewater training is such an integral part of any treatment system, we have been asked

to develop an online waste water training program with some of our materials.

Click here and Go straight to our WebSite - www.WastewaterELearning.com Take a sneak peek inside our training courses with our

ELearning

Demo Make sure to create an account and log in. Contact Environmental Leverage for more

information about obtaining this poster for your lab or setting up hands on

training, consulting and onsite audits.

|

Grease

control is a huge issue also that can contribute to foaming, filamentous

bulking and dewatering issues.

Grease

control is a huge issue also that can contribute to foaming, filamentous

bulking and dewatering issues.