Biological Products:

Bioaugmentation products for Wastewater applications in Papermills, Refineries, Chemical, Tanneries, Municipalities, Textiles, Steel, Agriculture, Animal feedlot, Gun Powder plant, Food and Beverage- Dairy Products, Orange Juice factory, Wineries, Cookie factory, Vegetable processing plant, Meat packing, Barbecue Restaurant, Aquaculture, Ornamental Ponds with algae , CAFO, Nursing homes, Military, Campgrounds, Universities, Regulatory agencies, River and Lake remediation

Lab Services:

Filamentous Identification Lab Service. One reason to identify filaments is to determine the filaments characteristics and then determine the type present. If the type is found out, a root cause can usually be associated with a particular filament. If the cause is known, then a correction can be made to alleviate problems. Chlorination is only a quick fix. Without process changes, filaments will grow back after chlorination. Wastewater Biomass Analyses and Cooling Tower Analyses also available

Training Materials:

Training is an integral part of any job. Not everyone is at the same level of training. Many people want beginning concepts and basics. Some need technical information or troubleshooting. Some want equipment, technology or process information. We have developed a full set of Basic training, Advanced training, Filamentous Identification the Easy Way as well as custom training CD's Manuals. We also provide hands-on training classes and soon will have an Online "E-University".

Audits and Consulting:

At Environmental Leverage® Inc., we have a team of experienced individuals who come into your plant with a fresh pair of eyes. The system is checked from influent to effluent. System optimization, equipment efficiency and operational excellence are key components explored. Key Benefits Equipment efficiency Total Cost of Operation reductions Reliability and safety An onsite audit is conducted to examine system parameters, process controls, and current monitor and control procedures. A physical walk-through is conducted, process flow diagrams are examined, previous design criteria are examined and current standard operating procedures are evaluated along with data logs.

|

Industry Troubleshooting - AquacultureLatest News!

What's New!

We have just added "Virtual Audits" to our capabilities. Check out our new Services. We are in the process of developing new courses for our ""Online E-University" in order to meet the needs of our global customers that cannot travel to our public classes.Visit our new website www.WastewaterElearning.com/Elearning

Aquafarming: Fish or Shrimp farming Since the supply of wild fish is declining, and some species, such as cod, striped sea bass, salmon, haddock, and flounder, have already been over fished, aquaculture, or fish farming, seems to be the solution to the problems created by the law of supply and demand and our increasing demand for seafood. Farm-raised fish currently account for about 15% of the market. There are 93 species of fin fish, seven species of shrimp, and six species of crawfish, along with numerous species of clams, oysters and shellfish that are currently being farm raised worldwide. In the next twenty years, aquaculture will surpass capture fisheries in supplying seafood to the world.

Aquacultural output, growing at 11 percent a year over the past decade, is the fastest growing sector of the world food economy. Aquaculture is the farming of aquatic organisms, including finfish, shellfish (mollusks and crustaceans), and aquatic plants. Fish farming is the principal form of aquaculture. It involves raising fish commercially in tanks or enclosures, usually for food for human consumption. Fish species raised by fish farms include salmon, catfish, tilapia, cod, carp, trout and others. Fish farming, or “aquaculture,” has become a billion-dollar industry, and more than 30 percent of all the sea animals consumed each year are now raised on these “farms.” The United Nations’ Food and Agriculture Organization reports that the aquaculture industry is growing three times faster than land-based animal agriculture, and fish farms will surely become even more prevalent as our natural fisheries become exhausted. Over 1100 species of fishes, molluscs and crustaceans directly contribute to production of the world’s major fisheries. There are many additional species contributing to smaller-scale fisheries. In aquaculture, although the majority of production comes from a few species, there are over 300 species, which do contribute.

Expanding at a rapid rate, fish farming now accounts

for over 30 percent of all fish protein consumed annually in the world. But

it is single-handedly responsible for the destruction of countless

ecosystems and the fishing communities that rely upon them, in some of the

most vulnerable marine environments on the planet. A typical salmon farm of 200,000 fish produces roughly the same amount of fecal matter as a town of 62,000 people.

Issues related to farming: pH Alkalinity Nitrification Dissolved Air Algae blooms

Regulations Bioaugmentation in Aquaculture The life of a farm-raised fish begins in temperature-controlled hatching tanks. From here, small fish (called "fry") are transferred to rearing areas where they grow to maturity. The fish may be raised in highly- controlled tanks or raceways (rectangular concrete enclosures up to 20 acres in size) constructed inland, or they may be raised in artificial enclosures in coastal estuaries.

Various types of fish farming exist.

In this kind of system fish production per unit of surface can be increased at will, as long as sufficient oxygen, fresh water and food are provided. Because of the requirement of sufficient fresh water, a massive water purification system must be integrated in the fish farm. A clever way to achieve this is the combination of hydroponic horticulture and water treatment. Fish food must contain a much higher level of protein (up to 60%), in order to achieve fish weight gain in small quarters. Quite a bit of the food is wasted, and also quite a bit of fish waste is deposited into the water. High BOD, as well as nutrient content due to the fish waste can be found in these types of farms.

Integrated

recycling systems One of the largest problems with freshwater aquaculture is that it can use a million gallons of water per acre (about 1 m³ of water per m²) each year. Extended water purification systems allow for the reuse (recycling) of local water. The largest-scale pure fish farms use a system derived (admittedly much refined) from the New Alchemists in the 1970s. Basically, large plastic fish tanks are placed in a greenhouse. A hydroponic bed is placed near, above or between them. When tilapia are raised in the tanks, they are able to eat algae, which naturally grows in the tanks when the tanks are properly fertilized. The tank water is slowly circulated to the hydroponic beds where the tilapia waste feeds commercial plant crops. Carefully cultured microorganisms in the hydroponic bed convert ammonia to nitrates, and the plants are fertilized by the nitrates and phosphates. Other wastes are strained out by the hydroponic media, which doubles as an aerated pebble-bed filter. In small systems the fish are often fed commercial fish food, and their waste products can help fertilize the fields. In larger ponds, the pond grows water plants and algae as fish food. Some of the most successful ponds grow introduced strains of plants, as well as introduced strains of fish.

Cage system Fish cages are synthetic fiber cages kept in existing water resources to contain and protect fish until they can be harvested. A few advantages of fish farming with cages are that many types of water can be used (rivers, lakes, filled quarries, etc.), many types of fish can be raised, and fish farming can co-exist with sport fishing and other water uses. However, fish are vulnerable to disease, poaching, and low levels of dissolved oxygen. In general, pond systems are easier to manage, and simpler to start. Control of water quality is crucial. Fertilizing, clarifying and pH control of the water can increase yields substantially, as long as eutrophication is prevented and oxygen levels stay high. Yields can be low if the fish grow ill from electrolyte stress. Many critical parameters are monitored and controlled, not only for the health of the fish, but the algae they may eat, also the bacteria that will help consume the excess organics and nutrients.

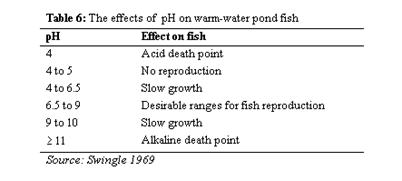

pH is important in aquaculture as a measure of the acidity of the water or soil. Fish can not survive in waters below pH 4 and above pH 11 for long periods. The optimum pH for fish is between 6.5 and 9. Fish will grow poorly and reproduction will be affected at consistently higher or lower pH levels (Table 6).

Alkalinity Alkalinity is the most

important thing when trying to establish nitrification in aquaculture.

Nitrifiers use the alkalinity as a food source, and the excess ammonia as an

energy source. 7.14 parts of alkalinity are required for every part of

excess ammonia in the water that is to be removed.

Oxygen is a critical component in the nitrification equation.

Higher levels of oxygen are required for nitrification than for carbon

removal. As ammonia is removed it is transformed.

4.5 parts of O2 are needed for every part of NH3 to be

degraded.

Nitrification- Ammonia can be toxic to fish. Toxic concentrations of NH3-N for short-term exposure vary between 0.6 and 2 mg/litre for many pond fish, and some effects can be seen at 0.1 to 0.3 mg/litre (Boyd 1979). Normally warm-water fish are more tolerant to ammonia than cold-water fish. To be safe, ammonia concentrations below 0.05 mg/litre as NH3-N and 1.0 mg/litre as TAN are recommended for long-term exposure. Nitrification is the process of bacteria converting the ammonia to a less toxic compound. Ammonia is converted to nitrates by bacteria. The safe values of NO3-N for many fish and invertebrates lie between 1000 to 3000 mg/litre (Colt and Tchobanoplous 1976).

First Conversion

(Ammonium to Nitrite)

Nitrosomonas bacteria

oxidize ammonium to nitrite via hydroxylamine.

NH4+ + 1.5 O2 --> NO2-

+ 2H+ + H2O Second Conversion

(Nitrite to Nitrate)

Nitrobacter bacteria convert

nitrite to

nitrate.

NO2- + 0.5 O2 --> NO3-

Nitrification also occurs 3-4 times slower than carbonaceous oxidation. Upsets to a plant can take nitrifiers weeks to recover for nitrification as opposed to days or hours for carbon bacteria. For each 1-gram of NH3-N oxidized to NO3, 0.15 grams of new bacteria cells are formed. Sludge generation from nitrifiers is minimal.

Dissolved Oxygen Dissolved oxygen is not only critical for the fish, but again, it can impact the biomass in the surrounding water also. Here are the fish limits for DO: Swingle (1969) developed a dissolved oxygen (DO) scale for warm-water fish: DO: < 0.3 mg/litre : Fish die after short-term exposure DO: 0.3 mg to 1 mg/litre : Lethal for long- term exposure DO: 1mg to 5 mg/litre: Fish survive, but growth is slow for long-term exposure DO ³ 5mg/litre : minimum for warm water fish (fast growth)

Nitrifiers require large amounts of oxygen, 4.5 parts of O2 are needed for every part of NH3 to be degraded. Facultative bacteria require oxygen and grow significantly faster than in an anoxic or anaerobic condition, with few byproducts that can impact the health of the fish.

Algae: Phytoplankton is often

used as a food source in some fish farms. Phytoplankton is mostly

autotrophic microscopic algae, which inhabit the illuminated surface waters

of the sea, estuaries, lakes, and ponds.

Phytoplankton can

include diatoms, green algae, dinoflagellates, Euglenophyceae and saltwater

Coccolithophorids. A main point of concern is the risk of algae blooms. When temperatures, nutrient supply and available sunlight are optimal for algal growth, algae multiply their biomass at an exponential rate, eventually leading to an exhaustion of available nutrients and a subsequent die-off. The decaying algal biomass will deplete the oxygen in the pond water and pollute it with organic and inorganic solvents (such as ammonium ions), which can (and frequently do) lead to massive loss of fish.

Toxicity Heavy metals in the water could harm fish growth and cause “body-curved disease” of fry. Water pollution (eutrophication) in case of excessive fertilization can deplete oxygen levels and kill the fish. Too many nutrients also can add high levels of ammonia, which are toxic to the fish. Different species of fish have different susceptibilities to carbon dioxide toxicity. In some species, excess carbon dioxide hinders the ability of the blood to hold oxygen. Produced during respiration and consumed during photosynthesis, carbon dioxide levels fluctuate throughout the day opposite to dissolved oxygen levels. High carbon dioxide levels lower the pH, which in turn affects the ratio of un-ionized to ionized ammonia. Chloride levels can affect fish health in two ways: as the major constituent of salinity or as a treatment to prevent nitrite toxicity. In systems with existing or chronic high nitrite levels, chloride will often be added to prevent the fish from succumbing to nitrite toxicity. Copper, in the form of copper sulfate, is often used in aquaculture systems as an algicide and bactericide; however high levels can be toxic to fish. High pH and alkalinity levels will complex copper, helping to reduce its toxicity. Dissolved oxygen levels can affect fish respiration, as well as ammonia and nitrite toxicity. Salinity and temperature are both factors that affect dissolved oxygen levels. High nitrite levels, combined with low chloride and dissolved oxygen concentrations, may result in methemoglobinemia, better known as brown blood disease. The greatest concern with pH is how it affects the toxicity of many other substances, including nitrite and ammonia.

In an established system, the water temperature controls the rate of all chemical reactions, and affects fish growth, reproduction and immunity. Drastic temperature changes can be fatal to fish.

Regulations:

On June 30 2004, The EPA establishing effluent limitations

guidelines (ELGs) for concentrated aquatic animal production (CAAP), or

aquaculture, facilities. The regulation will apply to CAAP facilities that

generate wastewater from their operations and discharge that wastewater

directly into waters of the The CAAP ELGs will help reduce discharges of

conventional pollutants, primarily total suspended solids. The regulation

will also help reduce non-conventional pollutants such as nutrients. To a

lesser extent, the regulation will reduce the discharge of drugs that are

used to manage fish health and chemicals, such as those used to clean fish

tanks and nets. Facilities covered-The final rule applies to existing and

new CAAP facilities with the following characteristics: Use flow-through, recirculating, or net pen systems Directly discharge wastewater Produce at least 100,000 pounds of fish a year.

Bioaugmentation in Aquaculture Bioaugentation is becoming more and more popular as the health of the fish, as well as growth and productivity becomes big business in Aquaculture. Bioaugmentation is using a feed additive and water

treatment product specifically formulated to Bioaugmentation can Reduce Odor, Increases Settleability, is safe to the Environment, Restores Water Quality, Environmentally Friendly, Contains No Chemicals, Removes Available Nutrients from Water, Leaves Little Nutrients or BOD for Algae to Grow, Allows for better production of Fish/shrimp species, and Reduces BOD and TSS thus allowing for EPA or regulatory permit levels to be met when discharge permits are applicable. Environmental Leverage™ Inc. bioaugmentation program can help with MicroClear™ 108.

Obviously there are numerous things to look at in Aquaculture. Water quality can significantly impact the productivity and health of the fish species. More information on these topics can be found on our website or by requesting information by email from the link below.

MicroClear® 108 for Shrimp and fish farms

Printable Pdf of MicroClear®

108 below:

Pollution Prevention Opportunities

|

Aquafarms

can be based on land or in the ocean. Land-based farms raise thousands of

fish in ponds, pools, or concrete tanks. Ocean-based aquafarms are situated

close to shorelines, and fish in these farms are packed into net or mesh

cages.

Aquafarms

can be based on land or in the ocean. Land-based farms raise thousands of

fish in ponds, pools, or concrete tanks. Ocean-based aquafarms are situated

close to shorelines, and fish in these farms are packed into net or mesh

cages. Toxicity

Toxicity Intensive (closed-circulation) aquaculture

Intensive (closed-circulation) aquaculture Catfish,

Clarias ssp., can breathe atmospheric air and can tolerate much higher

levels of pollutants than, e.g., trout or salmon, which makes aeration and

water purification less necessary and makes Clarias species especially

suited for intensive fish production. In some Clarias farms about 10% of the

water volume can consist of fish biomass.

Catfish,

Clarias ssp., can breathe atmospheric air and can tolerate much higher

levels of pollutants than, e.g., trout or salmon, which makes aeration and

water purification less necessary and makes Clarias species especially

suited for intensive fish production. In some Clarias farms about 10% of the

water volume can consist of fish biomass. Especially

when fish densities are high, the risk of infections by parasites like fish

lice, fungi (Saprolegnia ssp.), intestinal worms (such as nematodes or

trematodes), bacteria (e.g., Yersinia ssp, Pseudomonas ssp.), and protozoa

(such as Dinoflagellates) is much higher than in animal husbandry because of

the ease in which pathogens can invade the fish body (e.g. by the gills).

The same holds for water pollution or depletion of oxygen in the water,

which can ruin a fish crop within minutes. This means, intensive aquaculture

requires tight monitoring and a high level of expertise by the fish farmer.

Especially

when fish densities are high, the risk of infections by parasites like fish

lice, fungi (Saprolegnia ssp.), intestinal worms (such as nematodes or

trematodes), bacteria (e.g., Yersinia ssp, Pseudomonas ssp.), and protozoa

(such as Dinoflagellates) is much higher than in animal husbandry because of

the ease in which pathogens can invade the fish body (e.g. by the gills).

The same holds for water pollution or depletion of oxygen in the water,

which can ruin a fish crop within minutes. This means, intensive aquaculture

requires tight monitoring and a high level of expertise by the fish farmer.

We

have an entire training for nitrification if you need help. Also

nitrification is very mathematical. See nitrification math. Nitrifiers can

be added to supplement a system and speed up ammonia removal. MicroSolv 600l

is the product we would use to supplement a system if needed.

We

have an entire training for nitrification if you need help. Also

nitrification is very mathematical. See nitrification math. Nitrifiers can

be added to supplement a system and speed up ammonia removal. MicroSolv 600l

is the product we would use to supplement a system if needed. Fish

do not grow well when the DO concentration is below 25% of saturation for

long periods (Romaire 1985). Fish perform better when DO concentrations are

near saturation. Some authors recommend that the DO concentration in

aquaculture systems be kept at about 90% of saturation, as a minimum at all

times, for optimum performance.

Fish

do not grow well when the DO concentration is below 25% of saturation for

long periods (Romaire 1985). Fish perform better when DO concentrations are

near saturation. Some authors recommend that the DO concentration in

aquaculture systems be kept at about 90% of saturation, as a minimum at all

times, for optimum performance.  Phosphates

enter the water supply from many sources, including agricultural runoff and

sewage. Although phosphorus is an essential nutrient for bone formation and

is a primary ingredient in fertilizers, excessive levels can promote an

overabundance of algae.

Phosphates

enter the water supply from many sources, including agricultural runoff and

sewage. Although phosphorus is an essential nutrient for bone formation and

is a primary ingredient in fertilizers, excessive levels can promote an

overabundance of algae. MicroClear

MicroClear