What are Filamentous Bacteria

What's New!

We have just added "Virtual Audits" to our capabilities.

Check out our new Services. We are in the process of

developing new courses for our ""Online E-University" in order to meet the needs of our global customers that cannot travel to our public classes.Visit our new website www.WastewaterElearning.com/Elearning

What

are Filamentous Bacteria and why are they important to my system? What

are Filamentous Bacteria and why are they important to my system?

Filamentous Bacteria are a type of bacteria that can be found in a

wastewater treatment system.

They function similar to floc forming bacteria in that they degrade BOD

quite well. In small amounts, they are quite good to a biomass. They can add

stability and a backbone to the floc structure that keeps the floc from

breaking up or shearing due to turbulence from pumps, aeration or transfer

of the water.

In large amounts they can cause many problems.

Filaments are bacteria and fungi that grow in long thread-like strands or

colonies.

I do not have filamentous bacteria at my plant! Are

you sure? Check here.

Filamentous Identification-

lab testing inquiries

They are very good BOD removers

They add a backbone or rigid support network to the floc structure

Helps the floc structure to filter out fine particulate matter that will

improve clarifier efficiency.

They help the floc to settle if in small amounts.

They reduce the amount of "pin" floc.

They can interfere with separation and compaction of activated sludge and

cause bulking when predominant.

They can affect the sludge volume index (SVI)

They can cause poor settling if dominant.

They can fill up a clarifier and make it hard to settle, causing TSS

carryover

They can increase polymer consumption

They can increase solids production and cause solids handling costs to

increase significantly

Typical SSV30 with

Filamentous Bulking

before and after Chlorination

What are some of the Major Causes of Filamentous Bacteria?

• Low Dissolved Oxygen

• Low F/M (High F/M)

• Low Nutrient (N or P)

• Septicity/Sulfides

• Low pH

• Grease and Oil

Filamentous Bacteria- How do I know they are there or how can I monitor

them?

• Microscopic analyses

• Gram stains and Neisser stains should be performed to differentiate

certain characteristics of the filaments in order to identify them and

determine the cause of them so corrective action can be taken.

• Settleometer - SVI

Filamentous Identification should be used as a tool to monitor the health

of the biomass when a filament problem is suspected. Filamentous

Identification is used to determine the type of filaments present so that a

cause can be found and corrections can be made to the system to alleviate

future problems. All filamentous bacteria usually have a process control

variation associated with the type of filament present that can be

implemented to change the environment present and select out for floc

forming bacteria instead.

Killing the filaments with chlorine or peroxide will temporarily remove

the filaments, but technically it is a band-aid. A process change must be

made or the filaments will return with time eventually. Find out what

filaments are present, find out the cause associated with them and make a

process change for a lasting fix to the problems.

Filaments their causes and suggested controls- click on the filament to

link to that filament's specific page for more information

Low D.O. Filaments

Control

Type 1701 Adjust the aeration rates or

S. natans

F/M( based on aeration solids)

H. hydrossis

(Long RAS lines or sludge held too long in the clarifier can sometimes

cause the

growth of low D.O. filaments even if the aeration basin has sufficient D.O.

Wastes

with Limited Nutrients (N or P)

Control Wastes

with Limited Nutrients (N or P)

Control

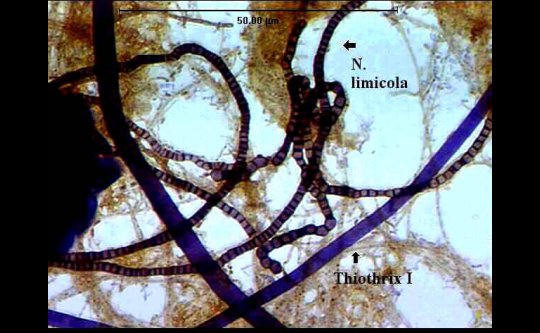

Thiothrix,

Nutrient addition BOD ratio

Type 021N and

N. limicola III

of 100:5:1 suggested

Low F/M ratios

Control

Type 0041

Increase RAS,

Type 1851

Increase WAS

Type 0803

Type 0675

Sulfide Compounds or Septic Wastes Control

Thiothrix,

Pre aeration or pre-

Beggiatoa

chlorination, Check solids holding times, clarifers, digestors

Type 021N, Type 0914 EQ tanks, process side holding tanks, dewatering tanks

Low FM and septic conditions

Type 0092, N. limicola II,

Same control as septic wastes

Type 0581, Type

0961, Type 0411

Low pH (< 6.5)

Control

Fungal filaments Adjust the pH

High Grease and Oil

Control

Nocardia, M. parvicella and

Type 1863 Optimize

Primary clarifier, Bioaugmentation

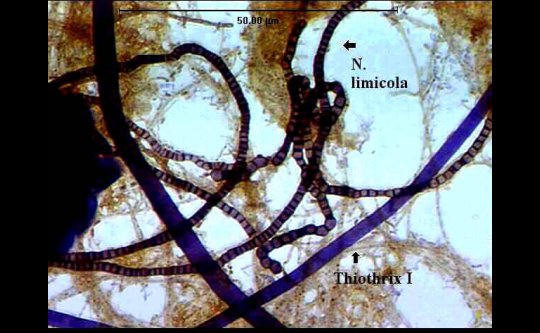

Some filaments have more than one version of the filament species, with

slightly different characteristics for identification.

N. Limicola I

N. Limicola II

N. Limicola III

Thiothrix I

Thiothrix II

Photomicrographs of Filaments

More

Environmental Leverage Inc. can help you with a Filamentous Identification

Wastewater Biomass Lab Analysis.

Filaments can be internally or externally and they can be free of the

floc structures or found intertwined in the floc. Most labs think that

filaments need to be extending from the floc in order to be a problem. That

is not true. Internal filaments can cause more problems than external

filaments. Think of internal filaments causing a structure like a sponge. It

will retain water easily and be harder to dewater, will be hard to compress

and will take up more space, thereby increasing solids handling costs.

Filaments present in the system do not always have to mean a problem.

Some filaments are good if they form a strong backbone and add a rigid

network to the floc. They help give the floc more structure and settle

faster. Filaments are good BOD degraders also. They are only a problem when

they become dominant. If filament abundance is in the abundant or excessive

range, having a Filamentous Identification performed is recommended.

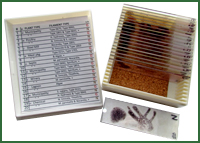

When

Gram and Neisser stains are performed for filamentous Identification, the

types of filaments found present will be noted on the Floc Characterization

sheet to the right of the filament section and will be noted on the Cover

Sheet. A Filament Causes sheet, Filamentous Predominance sheet and

corrective actions will be given and included also with the report. A

Filamentous Worksheet will be included. Individual sheets on the actual

filaments present in the sample will be included with more information on

that particular filament. When

Gram and Neisser stains are performed for filamentous Identification, the

types of filaments found present will be noted on the Floc Characterization

sheet to the right of the filament section and will be noted on the Cover

Sheet. A Filament Causes sheet, Filamentous Predominance sheet and

corrective actions will be given and included also with the report. A

Filamentous Worksheet will be included. Individual sheets on the actual

filaments present in the sample will be included with more information on

that particular filament.

Start your way now to a cleaner, brighter effluent with fewer hassles in

your waste treatment plant.

Ok, you convinced me. How do I go about sending in a sample?

Contact Jennifer or Laurie at Environmental Leverage- 1-630-906-9791 to set

up sampling.

What will I need to send in?

Send in 150 mls of MLSS in a small, plastic bottle with at least 1-2

inches of headspace/airspace in the bottle. This will keep sample from

becoming septic in transit and remain fresh for your analysis. Seal the bottle carefully. Send overnight

by UPS, Fed ex- etc. If possible, pack with blue ice to keep refrigerated.

1 -

Wastewater Biomass Only - $250.00

2 - Wastewater Biomass Analysis as above, plus Filamentous ID - $350.00 Full

Filamentous ID Analysis

Both Analysis Includes a CD with Microscopic photographs & digital videos,

troubleshooting advice from our expert staff.

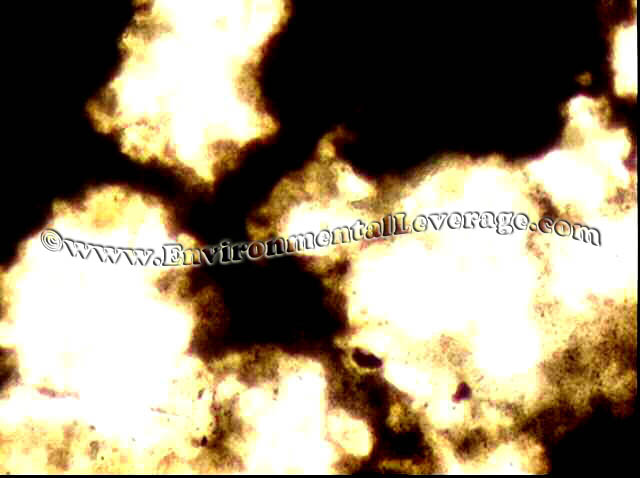

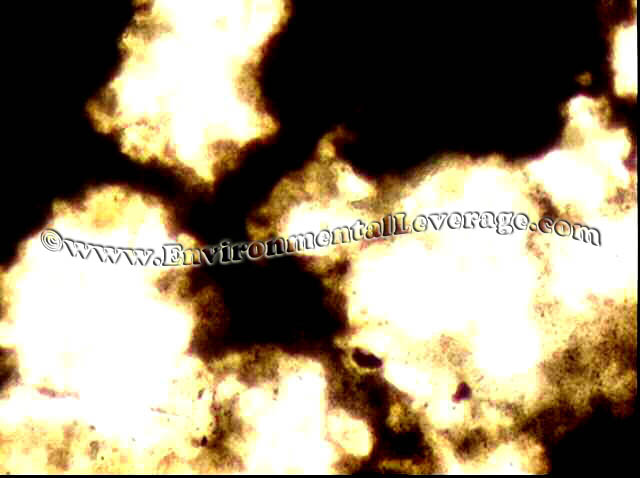

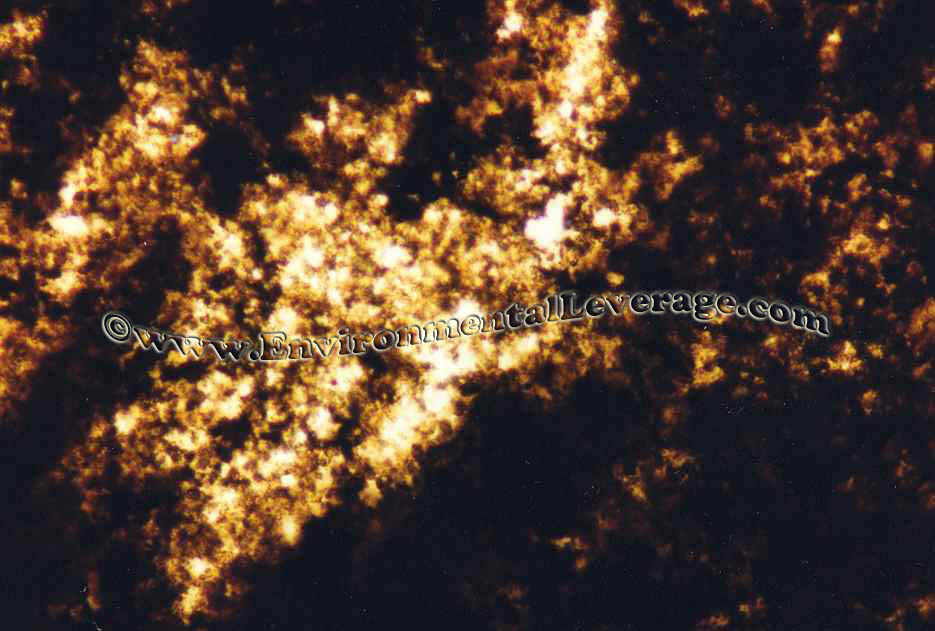

India Ink Stain- India Ink is used as a quick

and dirty test to tell one of two things.

This is an excellent quick and dirty test that can be used daily. One drop

of India ink is added to one drop of the biomass. Everything will be dark

except for the polymer generated by the biomass. A normal biomass will have

some bright areas relative to the size of the floc structures. Extremely

bright or excessive areas will indicate one of two things. A toxic shock to

the system or nutrient deficiency. If there are higher life forms present,

then a shock can instantly be ruled out and nutrient deficiency can be

verified.

Stains, what to use

and where to find them

If you are interested in having a

Filamentous Identification of your

wastewater system performed please fill out the form for sample

submission.

How are

your bugs doing?

Click on the links below for Filamentous Identification Information

1

Contact us today

and click this link to set up a Filamentous Identification of your MLSS

and start saving money at your plant

2 Wastewater Biomass

Lab Analyses

with Filamentous Identification

3 A full set of Stained Filaments - Microscope

Slide Set Pre-Made by Environmental Leverage Inc.

4 © Filamentous ID the

Easy Way™ - Training CD - packed full of samples from around the

world.

5

All

Wastewater Training Materials in printable Pdf form - Click this Link

6 Hands On

Wastewater Training Classes around the country - Earn CEU credits - Courses

taught by Tracy Finnegan, Principal Consultant of Environmental Leverage

Inc.

Wastewater Training Classes

Wastewater Training CD's

|

What

are Filamentous Bacteria and why are they important to my system?

What

are Filamentous Bacteria and why are they important to my system?

Wastes

with Limited Nutrients (N or P)

Control

Wastes

with Limited Nutrients (N or P)

Control

When

Gram and Neisser stains are performed for filamentous Identification, the

types of filaments found present will be noted on the Floc Characterization

sheet to the right of the filament section and will be noted on the Cover

Sheet. A Filament Causes sheet, Filamentous Predominance sheet and

corrective actions will be given and included also with the report. A

Filamentous Worksheet will be included. Individual sheets on the actual

filaments present in the sample will be included with more information on

that particular filament.

When

Gram and Neisser stains are performed for filamentous Identification, the

types of filaments found present will be noted on the Floc Characterization

sheet to the right of the filament section and will be noted on the Cover

Sheet. A Filament Causes sheet, Filamentous Predominance sheet and

corrective actions will be given and included also with the report. A

Filamentous Worksheet will be included. Individual sheets on the actual

filaments present in the sample will be included with more information on

that particular filament.