Service Options

What's New!

We have just added "Virtual Audits" to our capabilities.

Check out our new Services. We are in the process of

developing new courses for our ""Online E-University" in order to meet the needs of our global customers that cannot travel to our public classes.Visit our new website www.WastewaterElearning.com/Elearning

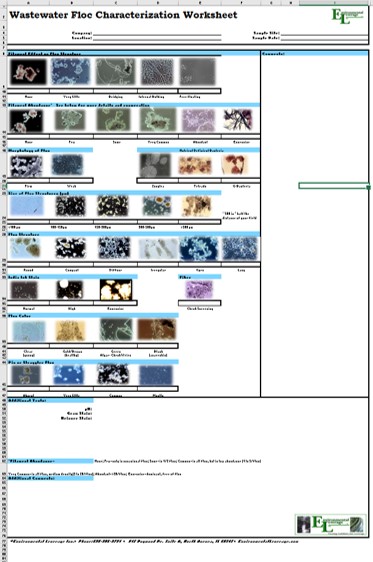

This is our standard analyses used to examine the biomass

in a system. A wastewater biomass analyses would consist of a number of

different things. A brief cover

letter explaining the overall health of your system as observed through the

sample. Any suggestions for troubleshooting that might be indicated by the

observations noted. The report includes an analysis of the floc, the higher

life forms and possible filamentous identifications if requested.

What is a wastewater biomass analysis?

The Wastewater Biomass Analyses consists of three sections, a

report that summarizes the findings and correlating process recommendations,

a Higher Life Form sheet and the Floc Characterization Sheet. Wet mounts,

India Ink stains as well as the use of Lactophenol Cotton blue are used on

the biomass.

Wastewater

Biomass Analyses $275.00 per sample.

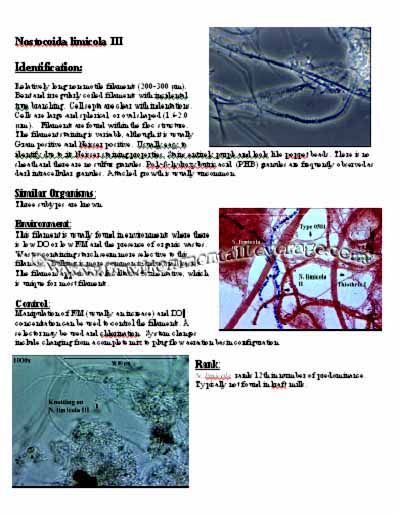

Filaments can be internal or external and they can be free of the floc structures or found intertwined in the floc. Filaments present in the system do not always have to mean a problem. Some filaments are good if they form a strong backbone and add a rigid network to the floc. They help give the floc more structure and settle faster. Filaments are good BOD degraders also. They are only a problem when they become dominant. If filament abundance is in the abundant or excessive range, having a Filamentous Identification performed is recommended. Filaments can be internal or external and they can be free of the floc structures or found intertwined in the floc. Filaments present in the system do not always have to mean a problem. Some filaments are good if they form a strong backbone and add a rigid network to the floc. They help give the floc more structure and settle faster. Filaments are good BOD degraders also. They are only a problem when they become dominant. If filament abundance is in the abundant or excessive range, having a Filamentous Identification performed is recommended.

One reason to identify filaments is to determine the filaments characteristics and then determine the type present. If the type is found out, a root cause can usually be associated with a particular filament. If the cause is known, then a correction can be made to alleviate problems. Chlorination is only a quick fix. Without process changes, filaments will grow back after chlorination.

Analyses consists of a orginal Wastewater Biomass analyses above, as well as

Filamentous Identification with Gram,

Neisser, Lactophenol Cotton Blue stains and India Ink stains. Filament

sheets for each filament identified are included as well as process

troubleshooting recommendations.

Filamentous Identification $375.00 Total.

SENDING BIOMASS SAMPLE PROCEDURE BELOW:

1 We have a Chain of Custody Excel form below

to use or your own form.

2 Please Call ahead to 630-906-9791 to ship sample. Add any information you

have that pretains to sample ie: BOD, DO, TSS, pH, etc.

Any testing numbers you have.

3 Leave 1-2 inches of head space in sample container for airspace.

4 No Blue Ice in Winter, Use Blue Ice in Summer and Do Not Use Ice Cubes

because of melting/leaks.

Download here Chain of Custody Form-Complete Form & Ship with

Biomass Sample

We are now offering GO

GREEN to our customers.

We will not send any paper copies of the report in the

mail. Just the CD with the full report, photos and videos.

Please let us know if you want to

GO GREEN for the environment.

Cooling towers can be a critical process in many

industrial production facilities. An industrial cooling tower can be the

perfect media for biological growth if not properly treated. Typical pH is

7-9 and temperatures may have a wide range. In a cooling tower, the water

trickles down a large surface area in order to air-cool the water. The

natural evaporation provides the cooling necessary to reuse the water. As

water evaporates, minerals and contaminants in the water concentrate. These

minerals and contaminants will eventually reach a concentration where they

will cause problems and interfere with the performance Cooling towers can be a critical process in many

industrial production facilities. An industrial cooling tower can be the

perfect media for biological growth if not properly treated. Typical pH is

7-9 and temperatures may have a wide range. In a cooling tower, the water

trickles down a large surface area in order to air-cool the water. The

natural evaporation provides the cooling necessary to reuse the water. As

water evaporates, minerals and contaminants in the water concentrate. These

minerals and contaminants will eventually reach a concentration where they

will cause problems and interfere with the performance

of both the tower and

the cooling system, itself. of both the tower and

the cooling system, itself.

Fouling and corrosion of the cooling tower can

impact treatment, and impact heat transfer losses causing decrease in

efficiency and increased power consumption. Biofouling can also destroy cooling towers if they

are made of lumber. Corrosion can occur on metal parts.

More seriously, such contaminants can be harmful to humans

who come in contact with them, like operational and maintenance personnel.

The most notable example has been the outbreaks of Legionnaires' disease,

affecting people in hotels, hospitals, office buildings, and other

locations, who have come into contact with cooled air from an air

conditioning system contaminated from cooling tower water of the air

conditioning plant.

For more details on

Cooling Tower Analyses and troubleshooting

Take a sneak peek inside our training courses with our

ELearning

Demo: Click Link. Make sure to create an account and log in.

Wastewater Training Options

The greatest equipment and the most efficient, dedicated workers can be

ineffective if they are not properly trained. At Environmental Leverage, we

have years of experience in many process areas and technical expertise on

equipment, systems and operations. Programs to optimize your system or

custom training can be tailored to increase the reliability and efficiency

of your plant.

Look

for self taught training materials and training courses below.

We have developed a full line of Training CD's and Elearning classes

for training and operator CEU's.

Elearning and General

Brochure Click for brochure

Since wastewater training is such an integral part of any treatment system, we have been asked

to develop an online waste water training program with some of our materials.

It is not

always easy to get on a plane or travel attend a wastewater training class. Now you will be able to

take waste water training courses at your leisure from your home or office.

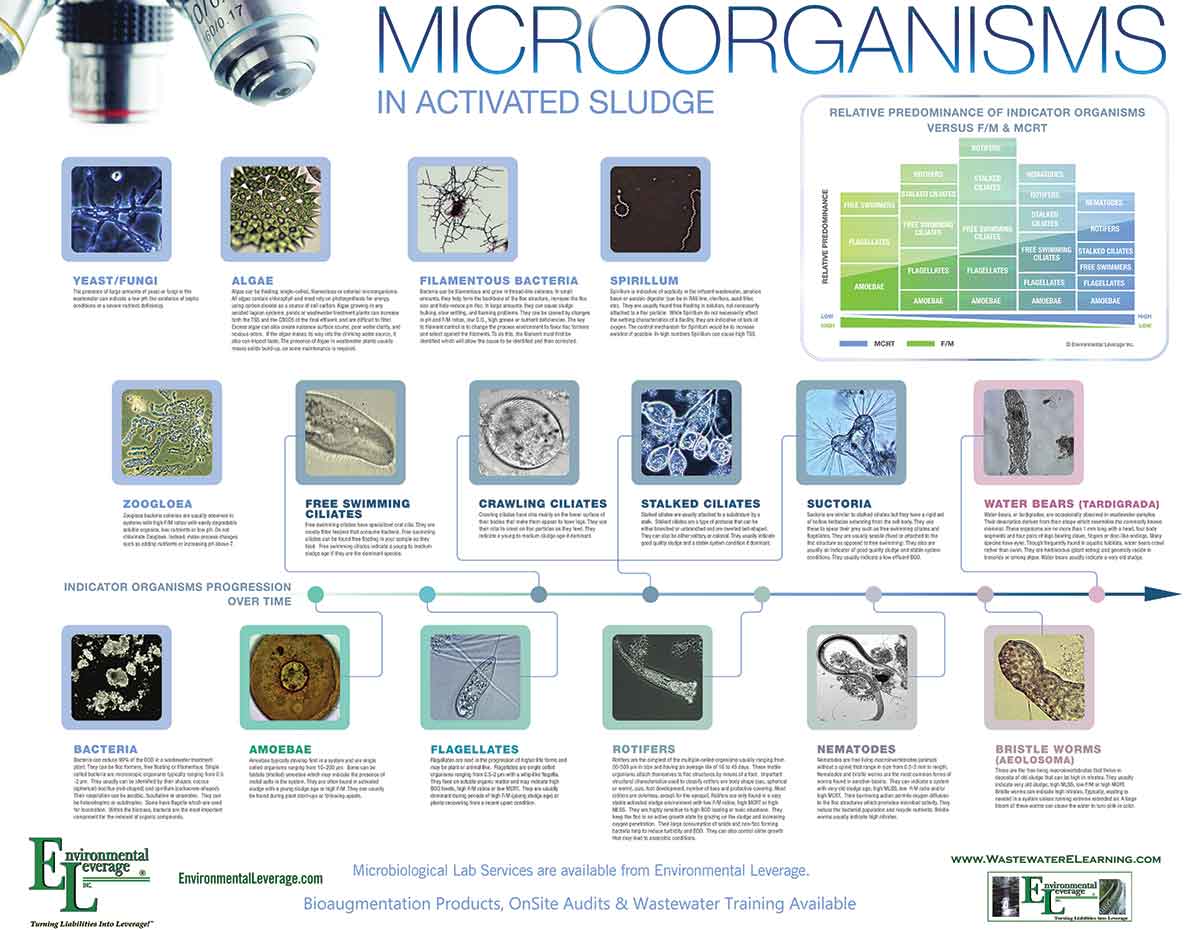

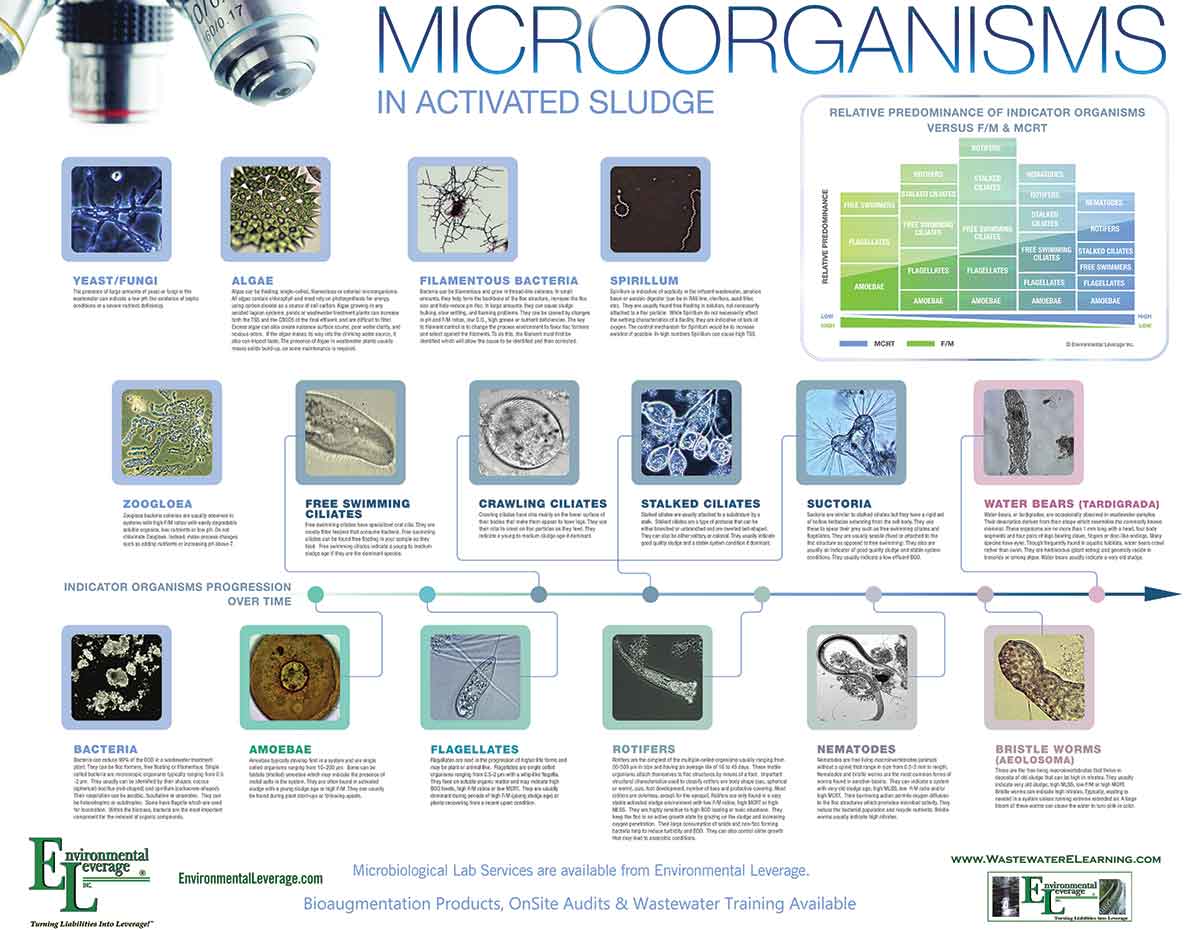

Lab Poster

Environmental Leverage Lab Poster

for Wastewater Training. This Microbiology Poster has photos as well as descriptions

and troubleshooting recommendations of common micro organisms found in most

wastewater treatment plants.

Contact Environmental Leverage for more

information about obtaining this poster for your lab or setting up hands on

training, consulting and onsite audits.

Email

admin@EnvironmentalLeverage.com or Call us at 630-906-9791

|

Cooling towers can be a critical process in many

industrial production facilities. An industrial cooling tower can be the

perfect media for biological growth if not properly treated. Typical pH is

7-9 and temperatures may have a wide range. In a cooling tower, the water

trickles down a large surface area in order to air-cool the water. The

natural evaporation provides the cooling necessary to reuse the water. As

water evaporates, minerals and contaminants in the water concentrate. These

minerals and contaminants will eventually reach a concentration where they

will cause problems and interfere with the performance

Cooling towers can be a critical process in many

industrial production facilities. An industrial cooling tower can be the

perfect media for biological growth if not properly treated. Typical pH is

7-9 and temperatures may have a wide range. In a cooling tower, the water

trickles down a large surface area in order to air-cool the water. The

natural evaporation provides the cooling necessary to reuse the water. As

water evaporates, minerals and contaminants in the water concentrate. These

minerals and contaminants will eventually reach a concentration where they

will cause problems and interfere with the performance