Biological Products:

Bioaugmentation products for Wastewater applications in Papermills, Refineries, Chemical, Tanneries, Municipalities, Textiles, Steel, Agriculture, Animal feedlot, Gun Powder plant, Food and Beverage- Dairy Products, Orange Juice factory, Wineries, Cookie factory, Vegetable processing plant, Meat packing, Barbecue Restaurant, Aquaculture, Ornamental Ponds with algae , CAFO, Nursing homes, Military, Campgrounds, Universities, Regulatory agencies, River and Lake remediation

Lab Services:

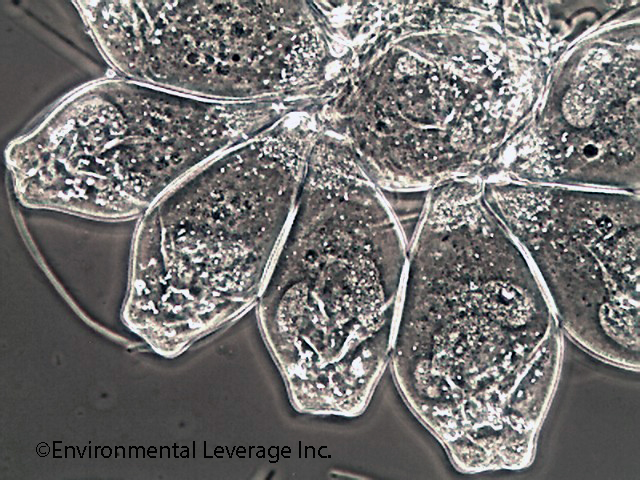

Filamentous Identification Lab Service. One reason to identify filaments is to determine the filaments characteristics and then determine the type present. If the type is found out, a root cause can usually be associated with a particular filament. If the cause is known, then a correction can be made to alleviate problems. Chlorination is only a quick fix. Without process changes, filaments will grow back after chlorination. Wastewater Biomass Analyses and Cooling Tower Analyses also available

Training Materials:

Training is an integral part of any job. Not everyone is at the same level of training. Many people want beginning concepts and basics. Some need technical information or troubleshooting. Some want equipment, technology or process information. We have developed a full set of Basic training, Advanced training, Filamentous Identification the Easy Way as well as custom training CD's Manuals. We also provide hands-on training classes and soon will have an Online "E-University".

Audits and Consulting:

At Environmental Leverage® Inc., we have a team of experienced individuals who come into your plant with a fresh pair of eyes. The system is checked from influent to effluent. System optimization, equipment efficiency and operational excellence are key components explored. Key Benefits Equipment efficiency Total Cost of Operation reductions Reliability and safety An onsite audit is conducted to examine system parameters, process controls, and current monitor and control procedures. A physical walk-through is conducted, process flow diagrams are examined, previous design criteria are examined and current standard operating procedures are evaluated along with data logs.

|

Filamentous IdentificationLatest News!

What's New!

We have just added "Virtual Audits" to our capabilities. Check out our new Services. We are in the process of developing new courses for our ""Online E-University" in order to meet the needs of our global customers that cannot travel to our public classes.Visit our new website www.WastewaterElearning.com/Elearning

I don't have filaments at my plant.......You might want to check again.

A common misnomer in many wastewater treatment plants is that unless they have filaments that are bridging and they can see them between the floc structures, they do not have filaments. In reality, internal bulking can cause more problems than slight bridging.

Many plants think there is only a problem when they have external filaments that are causing bulking problems. In reality there are three ways to cause bulking at a plant, internal filaments, external filaments or non-filamentous bulking- which can be caused by zooglea, fungi and in many municipalities or paper mills, fiber or tissue.

Wastewater Biomass Analyses document with Filamentous Identification.

What is the difference and how do they impact the plant? Let's take a closer look at all of these scenarios.

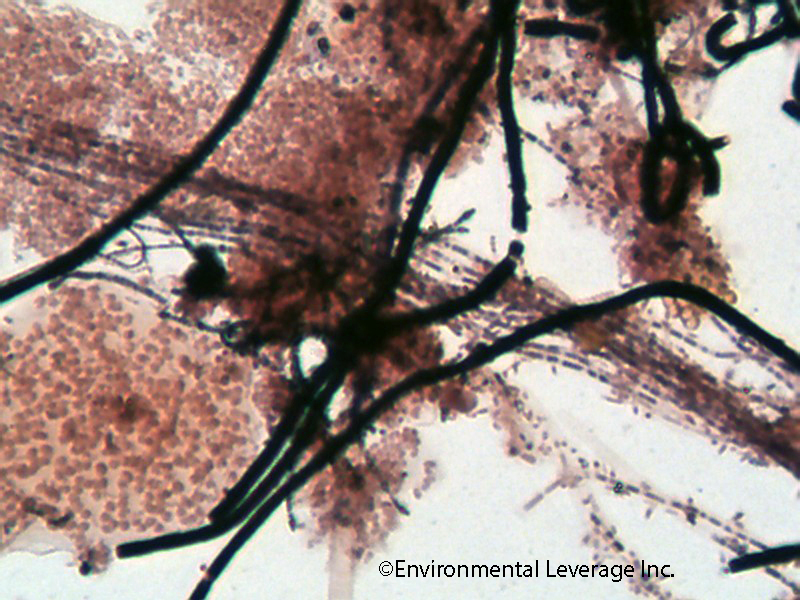

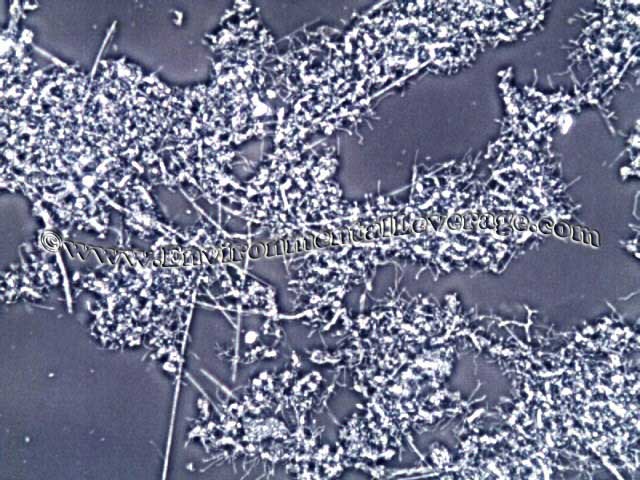

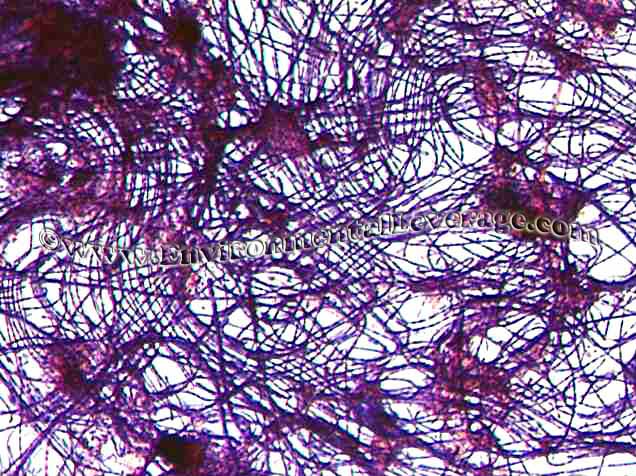

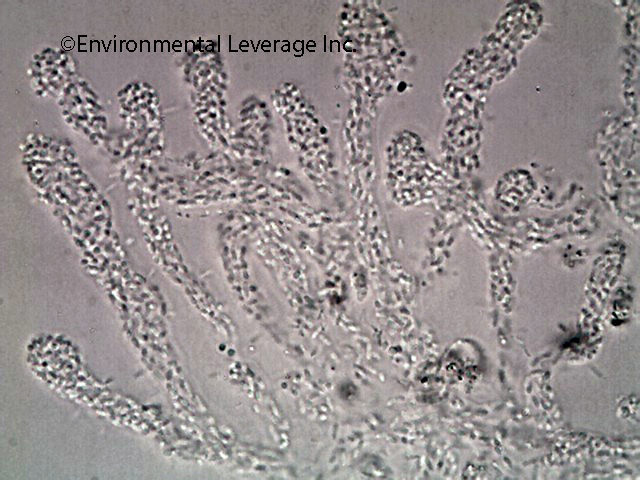

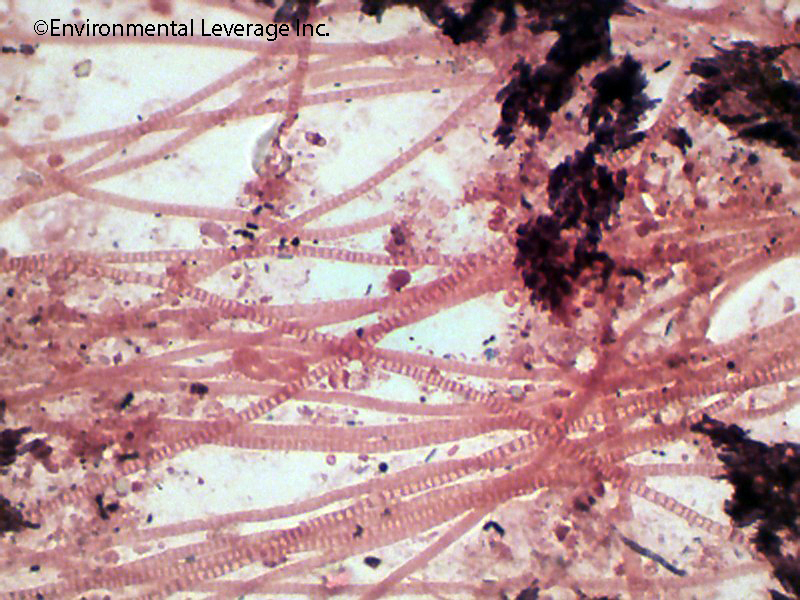

Filaments can be internal, external or free floating. Internal filaments are like a sponge. They can be hard to settle and dewater. External filaments keep the floc structures from coming together and compacting. Free-floating filaments can cause TSS problems. Zooglea and fungi can cause foaming, sliming or bulking. Let's first look at some samples from a few plants that have external bulking and what most operators think is the only case for filamentous problems. External filaments are those filaments that extend into the bulk solution and cause difficulty in settling. They form a bridge between the floc structures and make compaction difficult. They can take up large amounts of space in a clarifier or digestor or even aeration basin.

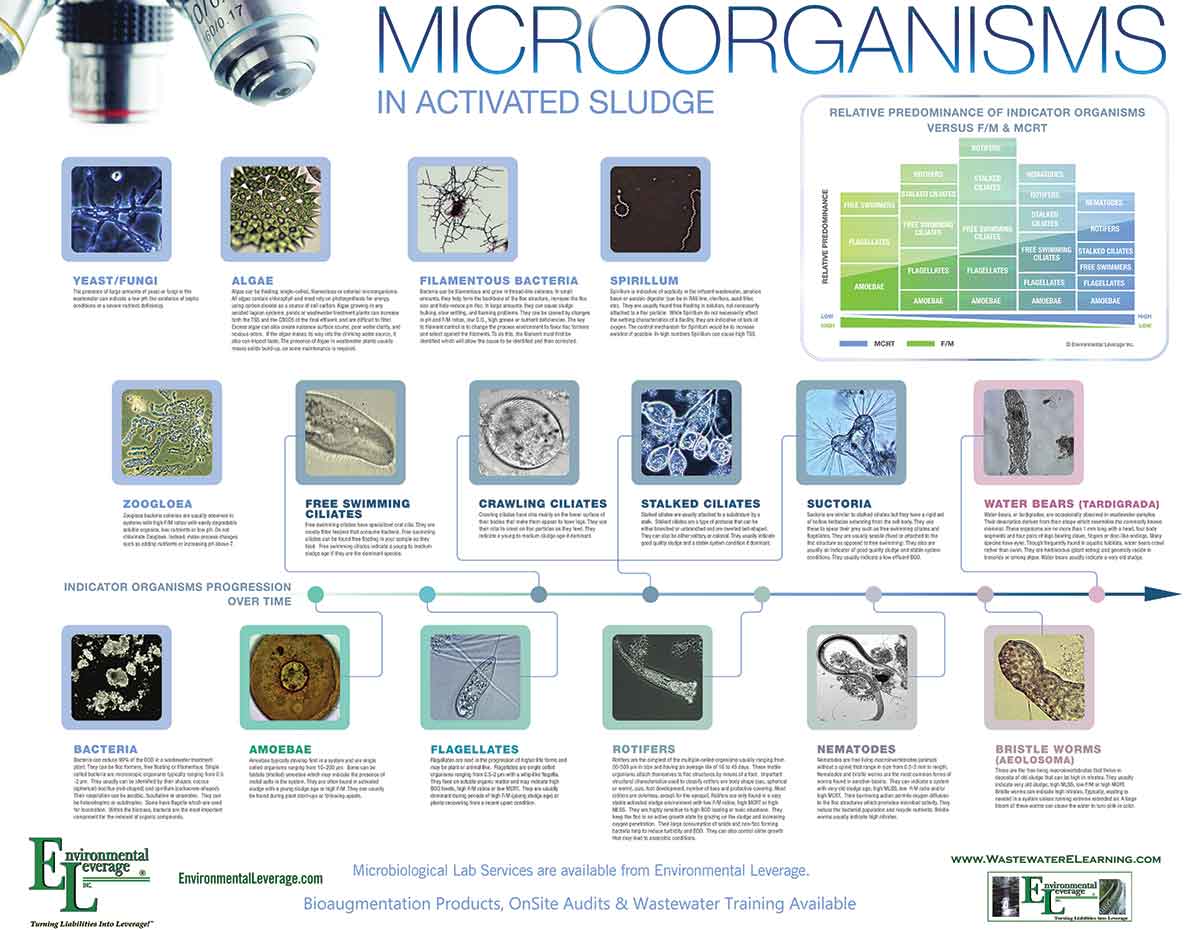

It is easy to pick out the filaments extending from the floc structure. The first photo shows the start of bridging, the second photo from a plant has abundant levels of filaments and the last one has excessive levels of filaments. This will make it hard to settle in the clarifier, hard to dewater and increase polymer consumption and increase solids hauling costs. This is typically what people think of when they talk about filamentous bulking. While you may think you have a large amount of bacteria when doing a Settleometer, in reality, the filaments are just taking up more space.

Typical SSV30 with

Filamentous Bulking

before and after Chlorination

How do you know if you have filamentous bulking or if you just have too

much MLSS in your settleometer?

Look closer, what appears to be nice floc, in reality is full of holes and spaces. Think of internal filaments as more like forming a sponge. Imagine trying to dewater a sponge. It would not only take quite a bit of pressure, but also polymer. It would hold water and not want to compact either. Internal filaments are just as much of a problem if not more. External filaments can at least be compressed with polymer. It takes more for internal filaments. Do not overlook them. Use your microscope and blow up the sample to 400x or 1000x and take a closer look.

When there are excessive levels of filaments, chlorination or peroxide will take forever to burn off these filaments. It is actually better to find out the cause, make a process change, slowly waste alongside chlorination and reseed with a commercial product if necessary. Otherwise, it could take 3-6 months to a year to make these filaments go away. A process change is always necessary, even if heavy chlorination is used. If the condition that caused the filaments to grow does not change, the filaments will always come back. They are very good BOD degraders, they just cause too many solids, dewatering problems and bulking in the clarifier.

All of these plants needed to make process changes in order to get rid of the filaments and reduce chances of violating on TSS due to filaments that were free floating.

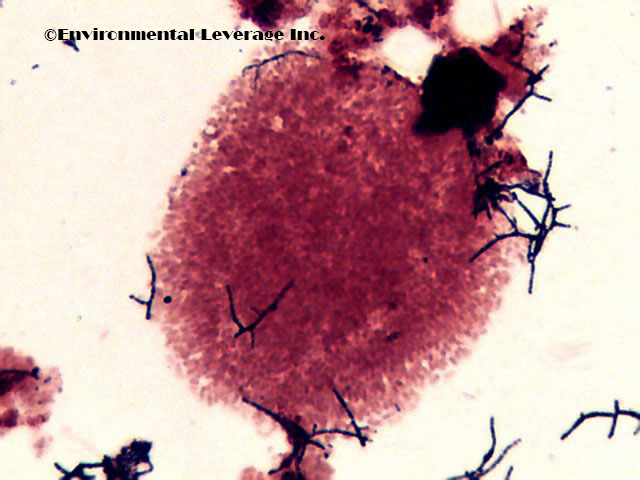

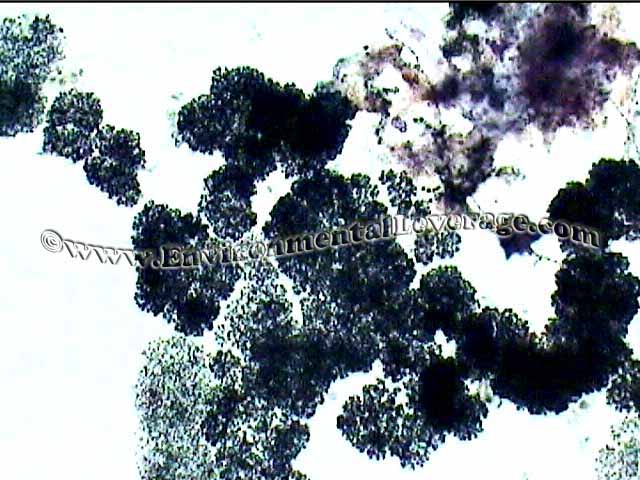

Zooglea and fungi can cause problems at a plant but are caused by very different situations in a plant and many times are overlooked.

Below is a perfect example of a plant that had problems and foaming. This is a municipal plant but they do have some industry that discharges to the plant. They were hit with a high loading and had tons of foaming on the plant. They assumed it was filamentous problems. Most operators do not look past 100 or 400x under their microscope. At 100x bright field it does not look too bad. Zoom in to 1000x and use some stains. Here is 1000 x with Gram and Neisser stain. It appears there is quite a bit of amorphous zooglea.

You cannot tell by looking at the foam what is really wrong with the plant. Pull a sample, get out your microscope and then look at what is present. The bugs will tell you what is going on and then you can fix it and change the process!

Still not convinced?

Electricity is usually the number one cost at a plant. Then solids handling and last polymers used for dewatering. The drier cake solids you can get, the less volume your sludge takes up, the lighter it weighs. If you are paying for solids handling costs based upon volume or weight, it is very critical.

How are

your bugs doing?

Wastewater Training Options The greatest equipment and the most efficient, dedicated workers can be ineffective if they are not properly trained. At Environmental Leverage, we have years of experience in many process areas and technical expertise on equipment, systems and operations. Programs to optimize your system or custom training can be tailored to increase the reliability and efficiency of your plant. Look for self taught training materials and training courses below.

We have developed a full line of Training CD's / Flash Drives and Elearning classes for training and operator CEU's.

Elearning and General Brochure Click for brochure Online Wastewater Training ELearning -Since wastewater training is such an integral part of any treatment system, we have been asked

to develop an online waste water training program with some of our materials.

Click here and Go straight to our WebSite - www.WastewaterELearning.com Take a sneak peek inside our training courses with our ELearning Demo Make sure to create an account and log in. Lab Poster

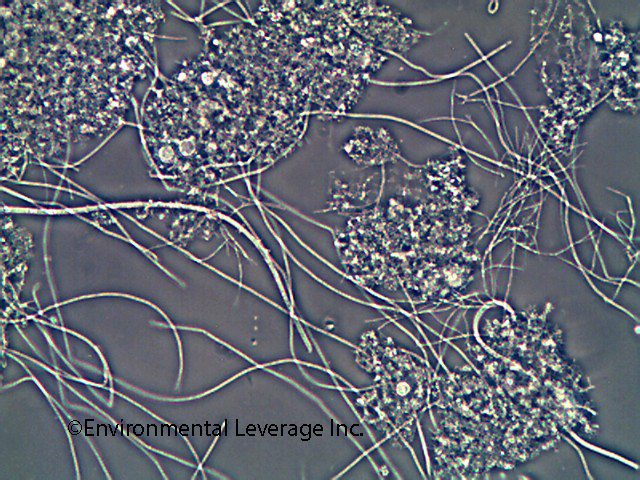

Environmental Leverage Lab Poster

for Wastewater Training. This Microbiology Poster has photos as well as descriptions

and troubleshooting recommendations of common micro organisms

Contact Environmental Leverage for more

information about obtaining this poster for your lab or setting up hands on

training, consulting and onsite audits.

Continuing Education Units CEU's are available when applicable and can be used for Wastewater Operators Liscense and Drinking Water Liscense when applicable. See Example for Drinking Water CEU's See Example for Wastewater CEU's

|

going on. Run a normal settleometer. Say for example your settling only

drops down to 800. Then run a 50/50 dilute sample. 50% water and 50% normal

MLSS. In reality, it should settle down to 400 in the same amount of time if

it was just too much MLSS. If in fact it is due to filamentous bulking, it

will probably not settle down to 400 or even close to that number. That will

be a quick indicator to look closer under the microscope and see just how

many filaments there are and what types are present so you can find a cause

and make a process change to make them go away. Remember, chlorine and

peroxide can kill filaments, but if you do not make a process change, they

will always come back. Change the system, and you select for the right type

of bacteria

going on. Run a normal settleometer. Say for example your settling only

drops down to 800. Then run a 50/50 dilute sample. 50% water and 50% normal

MLSS. In reality, it should settle down to 400 in the same amount of time if

it was just too much MLSS. If in fact it is due to filamentous bulking, it

will probably not settle down to 400 or even close to that number. That will

be a quick indicator to look closer under the microscope and see just how

many filaments there are and what types are present so you can find a cause

and make a process change to make them go away. Remember, chlorine and

peroxide can kill filaments, but if you do not make a process change, they

will always come back. Change the system, and you select for the right type

of bacteria