Biological Products:

Bioaugmentation products for Wastewater applications in Papermills, Refineries, Chemical, Tanneries, Municipalities, Textiles, Steel, Agriculture, Animal feedlot, Gun Powder plant, Food and Beverage- Dairy Products, Orange Juice factory, Wineries, Cookie factory, Vegetable processing plant, Meat packing, Barbecue Restaurant, Aquaculture, Ornamental Ponds with algae , CAFO, Nursing homes, Military, Campgrounds, Universities, Regulatory agencies, River and Lake remediation

Lab Services:

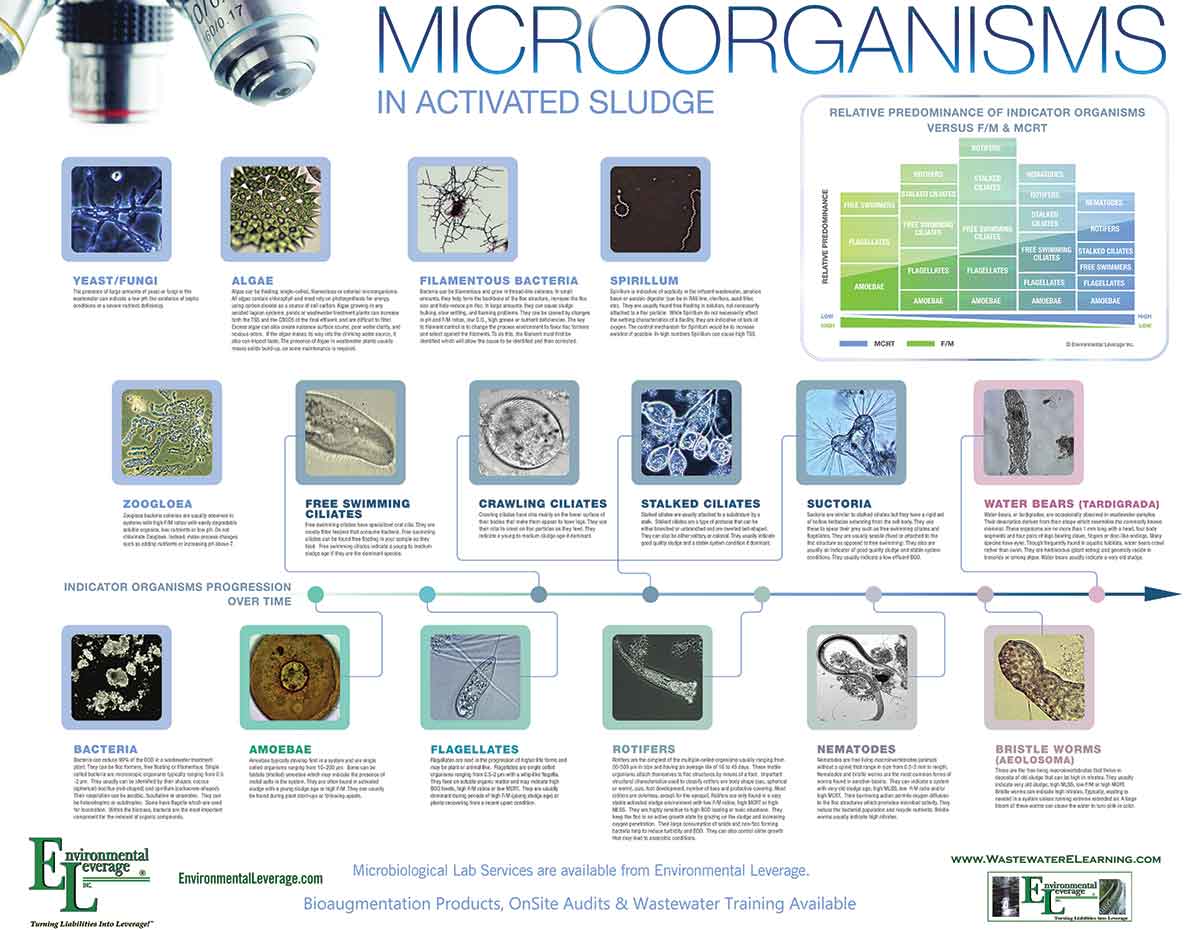

Filamentous Identification Lab Service. One reason to identify filaments is to determine the filaments characteristics and then determine the type present. If the type is found out, a root cause can usually be associated with a particular filament. If the cause is known, then a correction can be made to alleviate problems. Chlorination is only a quick fix. Without process changes, filaments will grow back after chlorination. Wastewater Biomass Analyses and Cooling Tower Analyses also available

Training Materials:

Training is an integral part of any job. Not everyone is at the same level of training. Many people want beginning concepts and basics. Some need technical information or troubleshooting. Some want equipment, technology or process information. We have developed a full set of Basic training, Advanced training, Filamentous Identification the Easy Way as well as custom training CD's Manuals. We also provide hands-on training classes and soon will have an Online "E-University".

Audits and Consulting:

At Environmental Leverage® Inc., we have a team of experienced individuals who come into your plant with a fresh pair of eyes. The system is checked from influent to effluent. System optimization, equipment efficiency and operational excellence are key components explored. Key Benefits Equipment efficiency Total Cost of Operation reductions Reliability and safety An onsite audit is conducted to examine system parameters, process controls, and current monitor and control procedures. A physical walk-through is conducted, process flow diagrams are examined, previous design criteria are examined and current standard operating procedures are evaluated along with data logs.

|

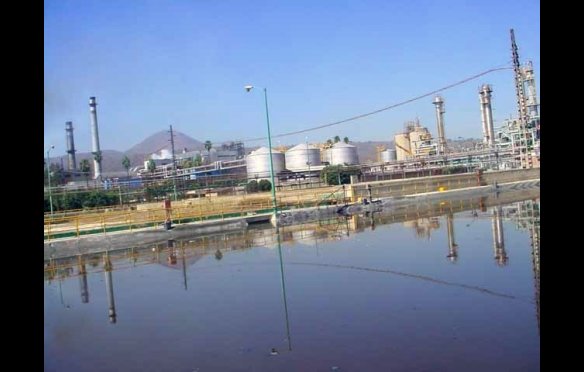

Chemical IndustryWhat's New!

We have just added "Virtual Audits" to our capabilities. Check out our new Services. We are in the process of developing new courses for our ""Online E-University" in order to meet the needs of our global customers that cannot travel to our public classes.Visit our new website www.WastewaterElearning.com/Elearning

The chemical industry is a keystone of the U.S. economy, converting raw materials (oil, natural gas, air, water, metals, minerals) into more than 70,000 different products and account for 24 % of the world's production. Foreign sales account for approximately 50% of total production.

Some of the benefits of Pollution Prevention or Biosolids Residuals and Reuse: Reduced Waste Treatment Costs Reduced off site treatment or disposal costs Reduced Capital and Operating Costs Reduced Manufacturing costs due to higher yield Reduced Environmental Compliance Costs ( fines or shutdowns) Income or savings from sale or reuse of waste by-product streams or solids The U.S. Chemical industry is the world's largest, accounting for 25% of world chemical production and 25% of all U.S. manufacturing energy use Solids Handling Alternatives- Biosolids Land Application as opposed to Landfills Beneficial Reuse- A new way to optimize your plant

Beneficial Reuse- What are some of the options available for hydrocarbon

waste that might be used as a fuel source? Oil and Grease- What is it and how to get rid of it Sign up to receive our Monthly Email Newsletter and be ahead of the curve! Chemical Plants and Refineries Case Histories

http://es.epa.gov/oeca/sector or by contacting Environmental Leverage

There are tons of files containing information on every subject from A to Z on the internet with standards, benchmarks and industry BMP's. The problems is, who has time to dig and find it all. It is not always in easy to find places. We have tried to show you some of the ones we though might be useful. There are links to the places where we found some of them in case you want to dig deeper on a particular subject and find out more.

Energy

Boiler and Cooling Tower Blowdown

Ashing on clarifier can significantly contribute to BOD and TSS problems. Check your clarifier beds. The solids are probably being held too long in your clarifier if you start to see scum build-up, ashing, floating solids or are having TSS problems.

Equalization tanks and Wetwells Many refineries and petrochemical plants have large storage tanks that they bleed into their secondary biological system. If wastewater is held too long in these tanks, it can become septic and impact the efficiency of the secondary biological system. Sometimes, something as simple as adding a small mixer or recirculation pump can help with septicity problems and filamentous bacteria growth.

Micronutrients or biological products can often times overcome difficulties that petrochemical plants have with changing influents and hard to degrade compounds. These products can also be used for onsite tank remediation to save thousands of dollars for the company by using bacteria to naturally clean up these tanks.

Since many Chemical plants make more than one product, they are constantly changing the food source for the bacteria in their wastewater treatment plant. This can sometimes cause problems in developing a healthy biomass. BOD and TSS problems are usually a result from the constant swings. The changes are sometimes reflected not only in the flow, but in the amounts and types of BOD. This makes it very hard to run a wastewater treatment plant without constant adjustments to the process parameters.

PetroChemical plants have numerous

wastewater issues in their plants. Some plants have too many amines

Why you should do a

Total Nitrogen Balance

Many Chemical plants have large storage tanks that

they bleed into their secondary biological system. If wastewater is

held

too long in these tanks, it can become septic and impact the efficiency of

the secondary biological system. Sometimes, something as simple as adding a

small mixer or recirculation pump can help with septicity problems and

filamentous bacteria growth.

Influent

chemistries may be composed of hard to degrade organics. Influent wastes may

contain aliphatic hydrocarbons, polynuclear aromatic hydrocarbons and

volatile aromatic carbon compounds. sometimes the systems need to be

enhanced with biological products to efficiently degrade such compounds as

benzenes, phenols, hydrocarbons, mercaptans, amines, organic alcohols, many

chlorinated and non-chlorinated hydrocarbons, surfactants and other

difficult to treat compounds.

Micronutrients or biological products can often times overcome

difficulties that petrochemical plants have with changing influents and hard

to degrade compounds. These products can also be used for onsite tank

remediation to save thousands of dollars for the company by using bacteria

to naturally clean up these tanks.

Chemical plants routinely have problems with filamentous bulking due to the fact that the influent stream consistently changes as new products or lines are changes. Bulking can cause an increase in polymer consumption and sludge handling costs.

Learn more about filaments and how to save money at your plant. Electricity is usually the number one cost at many wastewater treatment plants, but solids handling is second. Reducing the amount of solids that need to be dewatered, and hauled off can significantly reduce operating costs. Chemical plants sometimes have hard to treat organics that they send down to the wastewater treatment plant.

Learn how a biological program or micronutrients can help you plant meet tighter permit restrictions in a more efficient way. MicroSolv 400 Bacteria formulation for the Chemical Industry along with MicroClear M100 Micronutrients for Wastewater Applications

Beneficial Reuse

Many plants have spent caustic or Acid. Did you know a papermill could

possibly use the acid to raise lower their pH into their influent and save

them some money as well as allow their treatment plant to work more

efficiently? A steel mill might have spent fluids that could be used

for pH adjustment.

Case History-Tank Remediation at a PetroChemical Plant

The plant started the program and had the tank cleaned up in less than three

weeks, yet the tank had been sitting there filled for over three years. They

were tremendously impressed. They would have spent hundreds of thousands of

dollars to haul out the waste.

It does not really take long depending upon how much you seed the tank with. And the bacteria grow and multiply exponentially, so just sit back and wait. You wind up with a clean tank, clear effluent, and some bacteria residuals on the bottom of the tank that need to be disposed of- ( usually sent to the plants onsite dewatering system) or land applied.

Plant Issues 900 m3 of Contaminated Soil. Pollution: Crude oil. Several option where evaluated and E. H. Green/Environmental Leverage bioaugmentation program solution was elected. Due to the Hydrologic Area which the plant is located in ,the EPA of Israel instructed the plant to move the soil or reduce the TPH ( Total petroleum Hydrocarbons) from 842 to 100 ppm. Initial proposal assumed that it would take a few months due to high heat in the summer, and mainly the amount of soil and contamination to treat. After two weeks, TPH was down to 311, the following week, 133. Final TPH levels were pulled at 4 locations- 38, 39,81 and 37 were the final TPH readings, ~90-95.6% reduction in TPH ( Total petroleum Hydrocarbons) 80% cost reduction in treating the soil biologically including labor, nutrients, biological products, etc vs. hauling out the dirt as hazardous waste~ Soil Remediation Case History- Total Petroleum Hydrocarbons

Audits and Onsite Training and Consulting In order to "Audit" or Troubleshoot a Chemical wastewater treatment plant, a number of things need to be looked at. A physical walk-through of the plant needs to be conducted with visual observations noted. A microscopic analyses of the Biological portion of the waste treatment system needs to be conducted. Settleometer Testing needs to be conducted A sludge judge should be used on a Clarifier Examination of lab data- current testing procedures and results Walk through and correlation of process side to wastewater treatment plant operations A fully detailed final report is issued with process recommendations, system changes, areas for optimization and increased efficiency. For a full onsite audit of your plant- Contact Environmental Leverage inc. 630-906-9791

More troubleshooting for chemical plants: Troubleshooting Lagoon Systems

For a full onsite audit of your plant- Contact Environmental Leverage inc. 630-906-9791

Wastewater in the Fall- Problems and Solutions Summer impacts on your plant Hurricane or Severe Weather Upset recovery program Wild Weather Extremes that can impact your plant Beneficial Reuse

Solids Holding Lagoons-Winter BOD issues and bioaugmentation

Learn how Environmental Leverage can help your plant Bioaugmentation at Chemical Plants- impact on BOD and TSS Filamentous bacteria can be a problem is solids are held too long in a clarifier also.

Total System Optimization- Case History Lab Testing and Troubleshooting Newsletter

More to come . . . . .

Wastewater Training Options The greatest equipment and the most efficient, dedicated workers can be ineffective if they are not properly trained. At Environmental Leverage, we have years of experience in many process areas and technical expertise on equipment, systems and operations. Programs to optimize your system or custom training can be tailored to increase the reliability and efficiency of your plant. Look for self taught training materials and training courses below.

We have developed a full line of Training CD's and Elearning classes for training and operator CEU's.

Elearning and General Brochure Click for brochure Online Wastewater Training ELearning -Since wastewater training is such an integral part of any treatment system, we have been asked

to develop an online waste water training program with some of our materials.

Click here & Go straight to our WebSite - www.WastewaterELearning.com Take a sneak peek inside our training courses with our ELearning Demo Make sure to create an account and log in. Lab Poster

Environmental Leverage Lab Poster for Wastewater Training. This Microbiology Poster has photos as well as descriptions and troubleshooting recommendations of common micro organisms found in most wastewater treatment plants.

Contact Environmental Leverage for more

information about obtaining this poster for your lab or setting up hands on

training, consulting and onsite audits.

|

Many Chemical Plants have numerous side streams that can be isolated and

used elsewhere. Some examples are waste streams that are high in pH,

ammonia or phosphate that can be used by other waste treatment plants for

very low costs, usually cheaper than the cost to treat it and dispose of.

An orange juice plant used the peel oil for food additives. Low grade waste

oil could be used in odor control technology or in some essential oils for

fragrances that do not require the high levels of purity for human

consumption.

Many Chemical Plants have numerous side streams that can be isolated and

used elsewhere. Some examples are waste streams that are high in pH,

ammonia or phosphate that can be used by other waste treatment plants for

very low costs, usually cheaper than the cost to treat it and dispose of.

An orange juice plant used the peel oil for food additives. Low grade waste

oil could be used in odor control technology or in some essential oils for

fragrances that do not require the high levels of purity for human

consumption.

EPA Office

of Compliance Sector Notebook Project, Profile of the Chemical Industry. More information can be obtained on the EPA website

EPA Office

of Compliance Sector Notebook Project, Profile of the Chemical Industry. More information can be obtained on the EPA website The U.S. chemical industry consumed about 6.9 quads of energy in 2000.

This represents about 7% of domestic energy use and about 25% of all U.S.

manufacturing energy use. Nearly 50% of energy used is transformed into

chemical products. About one third of electricity used by the chemical

industry is produced onsite, primarily by means of cogeneration. The

industry has made significant improvements in energy efficiency over the

last decades, reducing energy use per unit of output by over 39% between

1974 and 1995.

The U.S. chemical industry consumed about 6.9 quads of energy in 2000.

This represents about 7% of domestic energy use and about 25% of all U.S.

manufacturing energy use. Nearly 50% of energy used is transformed into

chemical products. About one third of electricity used by the chemical

industry is produced onsite, primarily by means of cogeneration. The

industry has made significant improvements in energy efficiency over the

last decades, reducing energy use per unit of output by over 39% between

1974 and 1995.

Temperature can be sometimes be an issue. Influent temperatures

over 95° F or 100° F

can impact floc formation in the secondary biological system. While

many plants can get BOD degradation up to 115° F

or 120° F if consistent, floc formation is small,

pin floc persists and the system may require polymer addition in the

secondary clarifier or TSS problems will occur. Influent chemistries

may be composed of hard to degrade organics. Influent wastes may

contain aliphatic hydrocarbons, polynuclear aromatic hydrocarbons and

volatile aromatic carbon compounds. sometimes the systems need to be

enhanced with biological products to efficiently degrade such compounds as

benzenes, phenols, hydrocarbons, mercaptans, amines, organic alcohols, many

chlorinated and non-chlorinated hydrocarbons, surfactants and other

difficult to treat compounds.

Temperature can be sometimes be an issue. Influent temperatures

over 95° F or 100° F

can impact floc formation in the secondary biological system. While

many plants can get BOD degradation up to 115° F

or 120° F if consistent, floc formation is small,

pin floc persists and the system may require polymer addition in the

secondary clarifier or TSS problems will occur. Influent chemistries

may be composed of hard to degrade organics. Influent wastes may

contain aliphatic hydrocarbons, polynuclear aromatic hydrocarbons and

volatile aromatic carbon compounds. sometimes the systems need to be

enhanced with biological products to efficiently degrade such compounds as

benzenes, phenols, hydrocarbons, mercaptans, amines, organic alcohols, many

chlorinated and non-chlorinated hydrocarbons, surfactants and other

difficult to treat compounds.

in the

influent and need to nitrify. Some plants have no ammonia or amines and have

to add nitrogen as a nutrient for the bacteria. Nutrient control at

petrochemical plants can be an issue, depending upon which side you are

dealing with. Both need monitor and control for proper biological activity

and final effluent BOD and TSS controls along side of nutrient control.

in the

influent and need to nitrify. Some plants have no ammonia or amines and have

to add nitrogen as a nutrient for the bacteria. Nutrient control at

petrochemical plants can be an issue, depending upon which side you are

dealing with. Both need monitor and control for proper biological activity

and final effluent BOD and TSS controls along side of nutrient control.