Biological Products:

Bioaugmentation products for Wastewater applications in Papermills, Refineries, Chemical, Tanneries, Municipalities, Textiles, Steel, Agriculture, Animal feedlot, Gun Powder plant, Food and Beverage- Dairy Products, Orange Juice factory, Wineries, Cookie factory, Vegetable processing plant, Meat packing, Barbecue Restaurant, Aquaculture, Ornamental Ponds with algae , CAFO, Nursing homes, Military, Campgrounds, Universities, Regulatory agencies, River and Lake remediation

Lab Services:

Filamentous Identification Lab Service. One reason to identify filaments is to determine the filaments characteristics and then determine the type present. If the type is found out, a root cause can usually be associated with a particular filament. If the cause is known, then a correction can be made to alleviate problems. Chlorination is only a quick fix. Without process changes, filaments will grow back after chlorination. Wastewater Biomass Analyses and Cooling Tower Analyses also available

Training Materials:

Training is an integral part of any job. Not everyone is at the same level of training. Many people want beginning concepts and basics. Some need technical information or troubleshooting. Some want equipment, technology or process information. We have developed a full set of Basic training, Advanced training, Filamentous Identification the Easy Way as well as custom training CD's Manuals. We also provide hands-on training classes and soon will have an Online "E-University".

Audits and Consulting:

At Environmental Leverage® Inc., we have a team of experienced individuals who come into your plant with a fresh pair of eyes. The system is checked from influent to effluent. System optimization, equipment efficiency and operational excellence are key components explored. Key Benefits Equipment efficiency Total Cost of Operation reductions Reliability and safety An onsite audit is conducted to examine system parameters, process controls, and current monitor and control procedures. A physical walk-through is conducted, process flow diagrams are examined, previous design criteria are examined and current standard operating procedures are evaluated along with data logs.

|

Industry Troubleshooting-Summer Wastewater IssuesLatest News!

What's New!

We have just added "Virtual Audits" to our capabilities. Check out our new Services. We are in the process of developing new courses for our ""Online E-University" in order to meet the needs of our global customers that cannot travel to our public classes.Visit our new website www.WastewaterElearning.com/Elearning

Summer Wastewater Treatment Operational ProblemsIt’s summer again, and with the hot seasonal weather there sometimes can

be wastewater treatment problems. The most common problems encountered

during the summer months are too old a sludge age resulting in deteriorated

sludge solids quality (increased solids/TSS in the final effluent),

filamentous bulking caused by too low an F/M ratio (too old an SRT) and odor

control problems.

For every increase of 10° C in temperature, the reproductive rate of the

bacteria increases by one logs growth. Therefore, to hold a desired food to

microorganism ratio and sludge age, you need to increase the wasting rate in

an activated sludge plant. F/M ratio, i.e.; the Food to Mass ratio is the

number of bacteria in proportion to the amount of food or BOD to be

degraded. MCRT, SRT, etc. - Mean Cell Retention Time or Sludge Retention

Time is the amount of days the solids or biomass is held within the

wastewater treatment plant, this included the aeration basins and the

clarifier.

The solids concentration in the system will grow faster than the food supply, causing the older bacteria (usually those on the inside of a floc) to starve to death and lyse.

Ashing may occur in clarifiers or wastewater settling lagoons. This is when fine particles rise and spread over the

surface of the clarifier (and of the

Gassing can occur, causing sludge particles to float and again go over

the weirs contributing to TSS problems and bed settleability. This is due to

holding the solids too long in the clarifier and not enough free oxygen so

denitrification or gassification occurs. The old sludge can cause physical mixing problems in the dewatering operation, resulting in pockets with pure polymer to exist and other pockets in the sludge with no polymer - and this assumes that you are using the correct/optimum chemistry and charge. The pockets of unmixed polymer can then "blind" a belt on a belt press, causing poor dewatering results. The cure is not a "better" polymer, the cure is to readjust the sludge age!

Algae growth on the weirs can significantly increase and cause problems not only with clogging up the weirs, but with carryover into the final effluent. Algae can give a false higher BOD reading or cause TSS permit violations. Make sure to clean the weirs more often in the summer.

In some areas of the country, algae blooms may attract predators of that particular species of algae, which can result in nuisance problems. Example, you may see a species of a microscopic crustacean develop in the secondary clarifier, which will look like "streaks of blood", or at least streaks of a reddish color in the water. This is not a treatment problem as such, but can get people upset if they don’t know what is causing it.

Duckweed also can grow significantly on ponds in the summer time.

If the MLSS concentration is allowed to get too high, more dissolved oxygen will be required in the aeration basins. This is a real cost item (electrical utilities driving the aerators, particularly in diffused aeration systems), in addition to making it difficult within some systems to maintain adequate D.O. for the bacteria. Electricity is usually the number one cost in a waste treatment plant followed by solids handling. Oxygen transfer it is more difficult to achieve in hot water than cold water. If your D.O. is hard to maintain, try reducing the MLSS concentration you are holding in the aeration basin (via increased RAS and/or by wasting). This is where keeping track of your biomass solids balancing data is very valuable!

One last thought related to the above related to filamentous bulking versus just too high a mixed liquor concentration in the aeration basin. To assess sludge quality you can use a settleometer or graduated cylinder to measure the settling rate of the sludge. The results give you a good picture of what is happening in the secondary clarifier.

A desired settling rate in the settleometer should be;

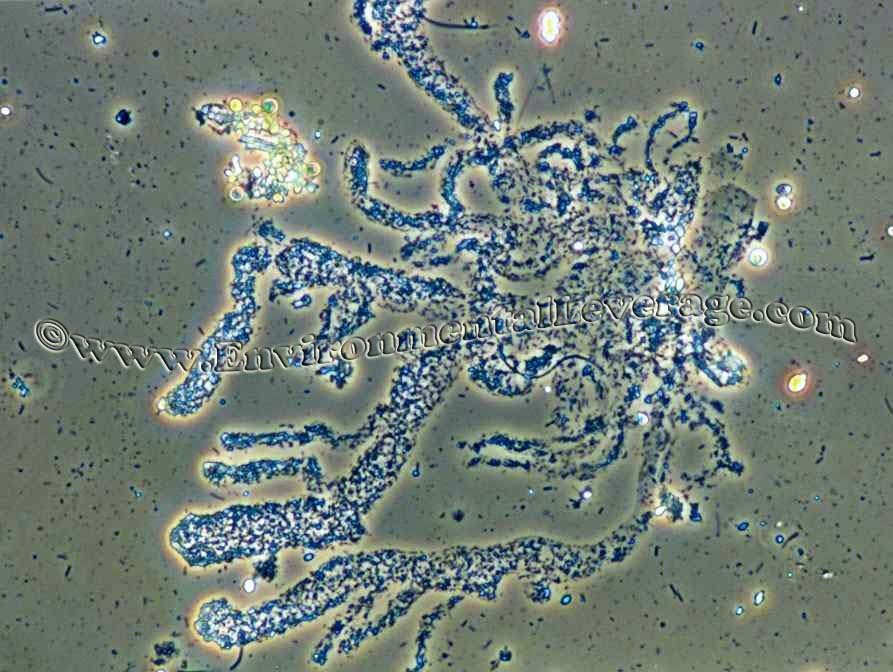

To determine if the problem is filamentous, use a microscope to observe these thread like bacteria in the wastewater treatment system. If only a few or no filaments exist, look for non-filamentous bulking caused by zooglea or polysaccharide bulking by doing an India ink stain under a microscope. If you do not have a microscope available, you can send in a sample to our lab for a Wastewater Biomass Analyses.

If the situation is a filamentous bulking problem, you usually apply chlorine to the system to kill the filaments and to speed up recovery. You must make a process change though according to the type of filament present. If you just chlorinate and kill the filaments and do not make any process changes, eventually, the filaments will come back. We also recommend coupling this action with bioaugmentation to maintain performance integrity in the system while you kill some of the indigenous biomass. Bioaugmentation helps compete with the filaments also and help speed up the recovery process.

Typical SSV30 with Filamentous Bulking before and after Chlorination

Filamentous Bacteria Control-Sodium hypochlorite (10 to 15%) is often used for this purpose as opposed to chlorine gas, as the hypo is much safer to handle. Sodium hypochlorite (NaOCl) will provide results comparable to chlorine gas, except that the chlorine is in a more dilute form. This actually can help provide better dispersion of the chlorine in the system, preventing uneven oxidation. For the record, industrial grade NaOCl has a specific gravity of 1.2, usually contains about 12.5% Cl2 content by the time you get it. It degrades with time and temperature, which means it actually contains about 1.0 pound of free available chlorine per gallon. Calcium hypochlorite (usually comes as a 70% solid) could also be used, but a makeup tank will be required to put it into solution prior to application and it tends to leave a calcium carbonate precipitate that will need to be removed from the feed tank. Also, store Ca(OCl)2 (also known as HTH) in a separate, dry area as it can react with any organic (in particular oily rags) causing spontaneous ignition (fire).

When using chlorine, remember that it aggressively reacts with ammonia (NH3-N) and/or sulfides such as H2S in water, which can increase the required dosage rates. Chlorine also reacts with many other impurities in wastewater such as amino acids (the enzymes and protein of the bacteria), carbonaceous matter (influent BOD), phenols, Fe+2, Mn+2, SO2, peroxides, sulfites, or cyanide (CN-) so don’t feed to the raw influent. The best place to feed is directly into the RAS line. Better contact is made with the filaments and less dilution from the influent takes place, so chemical costs can be cut.

Hydrogen peroxide (H2O2) can also be used, however, results can be spotty

as less is known about the mechanism in which it works. Some

Ozonation is another method. In South Africa, ozonation of activated sludge was studied for bulking control, with excellent results.

One last thought - if treating for filamentous bulking, it is not recommended to use a biocide, as they are all too persistent and will cause more harm to the floc forming bacteria than is desired. This comes up quite often, since many wastewater treatment plants may be using a biocide to treat the cooling towers or in the manufacturing process and figure that since it is on hand, it will work.

Making sure that your wastewater treatment system does not have dead spots, changing flow patterns, wasting more often, or increasing mixing can help. Sometimes additions of chemicals such as sodium nitrate are used where mechanical mixing is not possible. This will chemically prevent the formation of some sulfur compounds and biologically give the bacteria an alternate oxygen source, thus alleviating some of the odor causing problems. Remember bacteria will first go for free oxygen, then nitrates, then sulfates. If there is no oxygen, addition of nitrate is a safe alternative that can help avoid some odor problems. See our odor control sheet. Different bioaugmentation products and Wastewater Training programs are available for various applications and situations. Not all areas need the same method of correction. Wastewater Training is Critical as well.

More Wastewater Troubleshooting newsletters

Wild Weather

Sign up for our monthly newsletter

|

Bristle

worms can also be seen more readily in the summer months in wastewater

treatment plants as the sludge age

gets older. These are microscopic worms that can turn the foam on the

aeration basin pink in color, or the secondary clarifier surface color pink

due to the vast numbers of these worms that can develop. They are usually

found in the presence of high nitrates and older, well developed sludge.

Bristle

worms can also be seen more readily in the summer months in wastewater

treatment plants as the sludge age

gets older. These are microscopic worms that can turn the foam on the

aeration basin pink in color, or the secondary clarifier surface color pink

due to the vast numbers of these worms that can develop. They are usually

found in the presence of high nitrates and older, well developed sludge.  There

are some strains of

filamentous bacteria that can gain a foothold when the F/M gets too low

(or when the D.O. gets too low). This is where your

Wastewater Biomass Analysis (WBA’s) are invaluable! Using the microscope

as a daily monitor and control tool will help make running your wastewater

treatment plant easier. Filaments will cause bulking in the secondary

clarifier, eventually resulting in solids problems as they get washed over

the weirs.

There

are some strains of

filamentous bacteria that can gain a foothold when the F/M gets too low

(or when the D.O. gets too low). This is where your

Wastewater Biomass Analysis (WBA’s) are invaluable! Using the microscope

as a daily monitor and control tool will help make running your wastewater

treatment plant easier. Filaments will cause bulking in the secondary

clarifier, eventually resulting in solids problems as they get washed over

the weirs.

If

there are no filamentous bacteria present or polysaccharide problem is not

apparent, you can perform a diluted settlometer. Make 75% and 50% dilution

samples at the same time you do a settling test at 100% MLSS, to see if the

settling is much better in the diluted samples (compacts to less than 75% or

50% respectively of the level in the undiluted sample). If the settling is

improved by dilution, you may just have a solids glut on your hands. In this

case, reduce the MLSS concentration in the aeration basin by increasing the

RAS rate and/or the wasting rate. Also, check the flux on the secondary

clarifiers (solids loading per square foot surface area per day) to be

certain that the clarifier isn’t just under or over loaded versus it’s

design. Generally a flux of 15 to 25#/ft2/day is the design rate with CPI’s

sometimes running better at 10 to 12#/ft2/day, and pulp mills running better

in a 20 to 35#/ft2/day range. Too high/too low a flux will require polymer

usage.

If

there are no filamentous bacteria present or polysaccharide problem is not

apparent, you can perform a diluted settlometer. Make 75% and 50% dilution

samples at the same time you do a settling test at 100% MLSS, to see if the

settling is much better in the diluted samples (compacts to less than 75% or

50% respectively of the level in the undiluted sample). If the settling is

improved by dilution, you may just have a solids glut on your hands. In this

case, reduce the MLSS concentration in the aeration basin by increasing the

RAS rate and/or the wasting rate. Also, check the flux on the secondary

clarifiers (solids loading per square foot surface area per day) to be

certain that the clarifier isn’t just under or over loaded versus it’s

design. Generally a flux of 15 to 25#/ft2/day is the design rate with CPI’s

sometimes running better at 10 to 12#/ft2/day, and pulp mills running better

in a 20 to 35#/ft2/day range. Too high/too low a flux will require polymer

usage.

reports, however, claim that it can have an advantage over chlorine when low

dissolved oxygen is the stress, as the byproduct of this reaction is O2. As

with chlorine, peroxide will react with other impurities in the wastewater.

reports, however, claim that it can have an advantage over chlorine when low

dissolved oxygen is the stress, as the byproduct of this reaction is O2. As

with chlorine, peroxide will react with other impurities in the wastewater. If

the cause of the bulking is non-filamentous - Do NOT chlorinate,

as this will make the problem worse. For non-filamentous bulking,

correct the stress and use a polymer to aid in holding the sludge in the

clarifier (polymers will only aid in the initial settling rate, but they

don’t aid in compaction). Usually we are talking about using a coagulant, as

a flocculant can tend to hold in too much gas, which might cause the sludge

blanket to rise to the clarifier surface. Typically if is it due to zooglea

or nutrient deficiency, adding nutrients directly to the aeration basin,

sludge holding tank and clarifier simultaneously can clear up the problem in

hours. Make sure if excessive, that mixing occurs. Slime bulking can be easy

to get rid of if it is due to nutrient deficiency and enough nutrients are

added. Many cases, plants tend to be overcautious and do not add enough

nutrients. Be sure to add enough to solve the problem, but not cause excess

nutrients to go out with the final effluent.

If

the cause of the bulking is non-filamentous - Do NOT chlorinate,

as this will make the problem worse. For non-filamentous bulking,

correct the stress and use a polymer to aid in holding the sludge in the

clarifier (polymers will only aid in the initial settling rate, but they

don’t aid in compaction). Usually we are talking about using a coagulant, as

a flocculant can tend to hold in too much gas, which might cause the sludge

blanket to rise to the clarifier surface. Typically if is it due to zooglea

or nutrient deficiency, adding nutrients directly to the aeration basin,

sludge holding tank and clarifier simultaneously can clear up the problem in

hours. Make sure if excessive, that mixing occurs. Slime bulking can be easy

to get rid of if it is due to nutrient deficiency and enough nutrients are

added. Many cases, plants tend to be overcautious and do not add enough

nutrients. Be sure to add enough to solve the problem, but not cause excess

nutrients to go out with the final effluent. there are dead spots in a system or plant, such as corners, primary

clarifiers, sludge holding tanks, scum pits, lift stations, etc. The

increase in biological activity can deplete any oxygen available. Anoxic or

anaerobic activity will then start to increase causing malodors to increase

with the gasses generated.

there are dead spots in a system or plant, such as corners, primary

clarifiers, sludge holding tanks, scum pits, lift stations, etc. The

increase in biological activity can deplete any oxygen available. Anoxic or

anaerobic activity will then start to increase causing malodors to increase

with the gasses generated.