Biological Products:

Bioaugmentation products for Wastewater applications in Papermills, Refineries, Chemical, Tanneries, Municipalities, Textiles, Steel, Agriculture, Animal feedlot, Gun Powder plant, Food and Beverage- Dairy Products, Orange Juice factory, Wineries, Cookie factory, Vegetable processing plant, Meat packing, Barbecue Restaurant, Aquaculture, Ornamental Ponds with algae , CAFO, Nursing homes, Military, Campgrounds, Universities, Regulatory agencies, River and Lake remediation

Lab Services:

Filamentous Identification Lab Service. One reason to identify filaments is to determine the filaments characteristics and then determine the type present. If the type is found out, a root cause can usually be associated with a particular filament. If the cause is known, then a correction can be made to alleviate problems. Chlorination is only a quick fix. Without process changes, filaments will grow back after chlorination. Wastewater Biomass Analyses and Cooling Tower Analyses also available

Training Materials:

Training is an integral part of any job. Not everyone is at the same level of training. Many people want beginning concepts and basics. Some need technical information or troubleshooting. Some want equipment, technology or process information. We have developed a full set of Basic training, Advanced training, Filamentous Identification the Easy Way as well as custom training CD's Manuals. We also provide hands-on training classes and soon will have an Online "E-University".

Audits and Consulting:

At Environmental Leverage® Inc., we have a team of experienced individuals who come into your plant with a fresh pair of eyes. The system is checked from influent to effluent. System optimization, equipment efficiency and operational excellence are key components explored. Key Benefits Equipment efficiency Total Cost of Operation reductions Reliability and safety An onsite audit is conducted to examine system parameters, process controls, and current monitor and control procedures. A physical walk-through is conducted, process flow diagrams are examined, previous design criteria are examined and current standard operating procedures are evaluated along with data logs.

|

Polysaccharide coating- India Ink stainsLatest News!

What's New!

We have just added "Virtual Audits" to our capabilities. Check out our new Services. We are in the process of developing new courses for our ""Online E-University" in order to meet the needs of our global customers that cannot travel to our public classes.Visit our new website www.WastewaterElearning.com/Elearning

What is polysaccharide coating and what can I tell from it in my system?

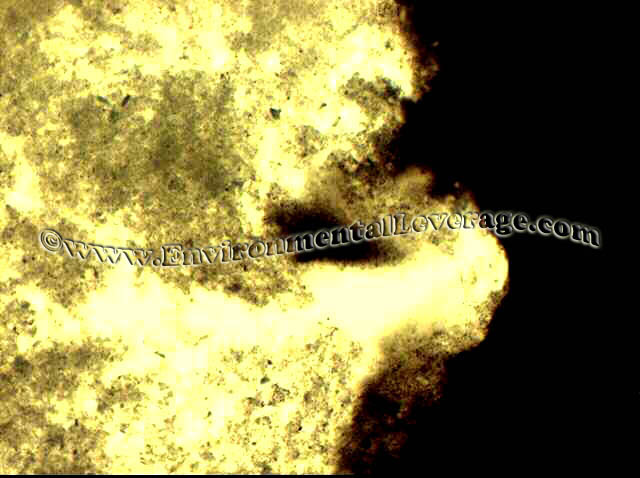

You can also perform an India ink staining on a biomass sample to check the levels of polysaccharide coating in the system. It is used to determine if the polysaccharide coating is normal or elevated. If the coating is high or excessive this can mean a nutrient deficiency or a recent toxic shock or high BOD loading. It is just a quick and easy test to determine how much polysaccharide is present but not why it has increased. It will be a quick indicator that there is a problem in your wastewater treastment plant and you should do some further checking into the system parameters.

Standard procedures are to add one drop of India ink on a wet mount to

one drop of the biomass. Everything will be dark except for the polymer

generated by the biomass. A normal biomass will have some bright areas

relative to the size of the floc structures.

If high, it can indicate a lack of nutrients or a recent shock to the wastewater treatment system. If there are tons of higher life forms present, you can probably rule out a shock and toxicity.

If a wastewater treatment plant has wide fluctuations on the influent loading, nutrient control should closely resemble the loading on the system. Nutrients levels and BOD Loading needs to be closely monitored and correlated to optimize and control a system. Nutrient deficiency can also cause excessive growth of filaments. It also can cause development of poor floc structures that either generate high levels of slime that are hard to dewater and increase polymer consumption but also can cause small, poor floc development and increase the level of TSS.

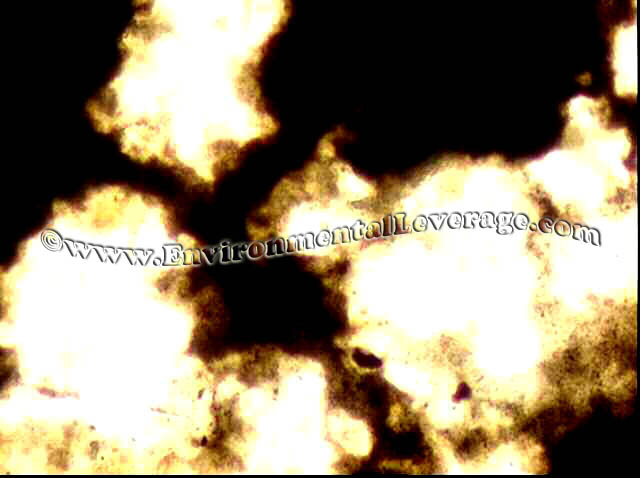

This photo shows only bright spots where the floc structures are present. The photo on the right has high polysaccharide coating and you can see where the polysaccharide coating extends beyond the actual floc particles and is streaming.

The photos on the bottom show the beginning of high polysaccharide coating

These two photos show very high to excessive polysaccharide coating. See how the coating is extremely intense and almost sliming over the edges of the floc structures.

Zoogleal bacteria and polysaccharide bulking due to this species is an entirely different thing than normal high polysaccharide coating.

See Zoogleal bacteria in wastewater training sheets.

|

Bacteria

naturally produce glycocalyx, a polysaccharide coating for a number of

reasons. Polysaccharide coating is a slime layer thinner than a capsule. It

is produced to protect the bacterial cells in cases of toxic shock

conditions. It also is produced to trap nutrients or food near the cell for

easier digestion. It is also used to bind the cells together to form floc.

The photo on the left shows a Gram stain of bacteria in a wastewater

treatment plant. The pink slimy areas show the high polysaccharide coating

produced by undesirable bacteria in a wastewater treatment system.

Bacteria

naturally produce glycocalyx, a polysaccharide coating for a number of

reasons. Polysaccharide coating is a slime layer thinner than a capsule. It

is produced to protect the bacterial cells in cases of toxic shock

conditions. It also is produced to trap nutrients or food near the cell for

easier digestion. It is also used to bind the cells together to form floc.

The photo on the left shows a Gram stain of bacteria in a wastewater

treatment plant. The pink slimy areas show the high polysaccharide coating

produced by undesirable bacteria in a wastewater treatment system.