Biological Products:

Bioaugmentation products for Wastewater applications in Papermills, Refineries, Chemical, Tanneries, Municipalities, Textiles, Steel, Agriculture, Animal feedlot, Gun Powder plant, Food and Beverage- Dairy Products, Orange Juice factory, Wineries, Cookie factory, Vegetable processing plant, Meat packing, Barbecue Restaurant, Aquaculture, Ornamental Ponds with algae , CAFO, Nursing homes, Military, Campgrounds, Universities, Regulatory agencies, River and Lake remediation

Lab Services:

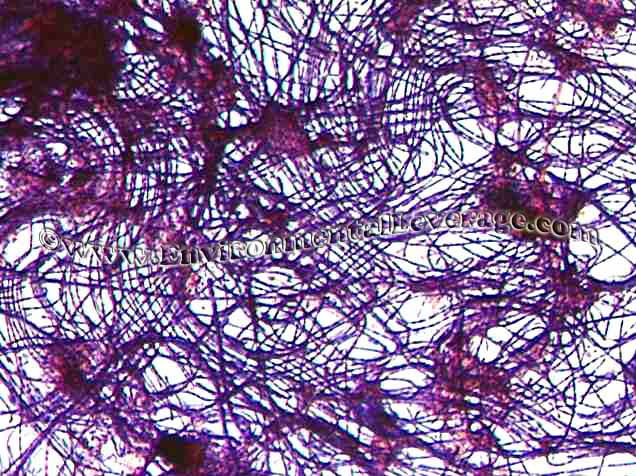

Filamentous Identification Lab Service. One reason to identify filaments is to determine the filaments characteristics and then determine the type present. If the type is found out, a root cause can usually be associated with a particular filament. If the cause is known, then a correction can be made to alleviate problems. Chlorination is only a quick fix. Without process changes, filaments will grow back after chlorination. Wastewater Biomass Analyses and Cooling Tower Analyses also available

Training Materials:

Training is an integral part of any job. Not everyone is at the same level of training. Many people want beginning concepts and basics. Some need technical information or troubleshooting. Some want equipment, technology or process information. We have developed a full set of Basic training, Advanced training, Filamentous Identification the Easy Way as well as custom training CD's Manuals. We also provide hands-on training classes and soon will have an Online "E-University".

Audits and Consulting:

At Environmental Leverage® Inc., we have a team of experienced individuals who come into your plant with a fresh pair of eyes. The system is checked from influent to effluent. System optimization, equipment efficiency and operational excellence are key components explored. Key Benefits Equipment efficiency Total Cost of Operation reductions Reliability and safety An onsite audit is conducted to examine system parameters, process controls, and current monitor and control procedures. A physical walk-through is conducted, process flow diagrams are examined, previous design criteria are examined and current standard operating procedures are evaluated along with data logs.

|

All wastewater foam is not alikeLatest News!

What's New!

We have just added "Virtual Audits" to our capabilities. Check out our new Services. We are in the process of developing new courses for our ""Online E-University" in order to meet the needs of our global customers that cannot travel to our public classes.Visit our new website www.WastewaterElearning.com/Elearning

Are you having problems with Grease? Low nutrients and high loading due to industry can also cause foaming as well as septicity?

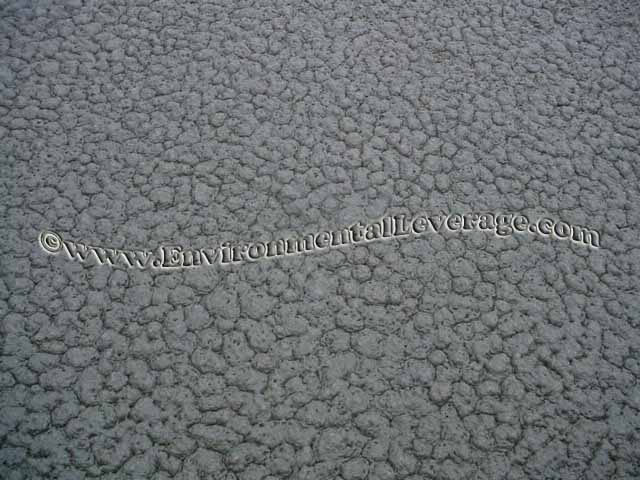

This is a picture of foam from a wastewater treatment plant that everyone said had to have problems with Nocardia or Microthrix. No one had ever looked under the microscope at the actual filaments or did a Gram or Neisser stain. In reality, this plant had too many solids in one of three basins and was also holding solids too long in the clarifier. The biomass had N. Limicola as the dominant filament. The plant needed to make a number of process changes as opposed to just " adding bacterial product" as a quick fix.

Process monitor and control were big wastewater training recommendations to this plant. All three basins were "not alike" in reality. Flows to each were changed over the years as old pipes became clogged. MLSS was not measured in each basin. Too many solids in one of the basins that only had the foaming problem were detected. Changes to step feed were also recommended since the final basin was also low on F/M. D.O. levels were not checked in each basin. Small changes in that also helped create conditions that literally caused the filamentous bacteria to thrive when they finally reached the last basin in the process.

Always do a walk through on your plant, look for trouble areas. Are you creating dead spots in the primary that can cause problems? In the secondary, in the clarifier, in the sludge holding tank, digestors or in the dewatering and returned supernatant?

Not all foam is bad -but it usually indicates a condition that is going on in your basin- learn what the colors mean. . . . These are the typical troubleshooting foaming charts- be careful though and use your microscope or you may make the wrong interpretation as to what is causing the foam and how to fix it.

Troubleshooting Secondary Wastewater Treatment Systems:

Foaming

Problems

Plants with foaming in the clarifier

Nocardia Foam

M parvicella foam Stable dark brown greasy foam that can get thick enough to have a crust- plant with Microthrix problems due to grease problems in the lift station. Adding bio block (MicroBlock™) bioaugmentation can help reduce grease upstream that causes problems in the plant.

Zoolgeal bulking due to high BOD loading from industry pretreatment at a municipality

Foaming due to septicity at a municipality and resulting in heavy filaments. When heavy filaments are present we can help with a microscopic biomass analysis with filamentous Identification. Click here for filamentous information

High foaming - white crisp foam- due to young sludge or high recent BOD loading

Normal aeration basin foaming due to diffused aerators

Keeping track in a daily log sheet, using photographs, correlating data to MLSS and to settlometer data as well as using the microscope are simple wastewater training suggestions and are all ways to help you understand what is going on in your wastewater treatment system. Remember - it is in reality a "bug factory - you are growing bacteria to make clean water! Start thinking like a bug. . .

Click on the links if you need more information on our Filamentous Identification the Easy Way™ Training CD or on Internet wastewater training on Filamentous bacteria, causes and controls

How are your bugs doing?

I do not have filaments at my plant

Click on the product pictures below for more information on bioaugmentation in your system

|

The

common misconception is that if you have foam on the surface of your aeration

basin, you must have Nocardia. Not all wastewater treatment plants or systems have foam due to Nocardia- Some

have Microthrix- Some just have too many solids and some low D.O.. . . . . .. .

Some have zoogleal bulking. Sometimes foaming can be due to Zooglea and other

times due to Septicity. Do not just assume what your foam cause is. Use your

Microscope and let the bacteria present tell you how to fix your plant.

The

common misconception is that if you have foam on the surface of your aeration

basin, you must have Nocardia. Not all wastewater treatment plants or systems have foam due to Nocardia- Some

have Microthrix- Some just have too many solids and some low D.O.. . . . . .. .

Some have zoogleal bulking. Sometimes foaming can be due to Zooglea and other

times due to Septicity. Do not just assume what your foam cause is. Use your

Microscope and let the bacteria present tell you how to fix your plant.