Biological Products:

Bioaugmentation products for Wastewater applications in Papermills, Refineries, Chemical, Tanneries, Municipalities, Textiles, Steel, Agriculture, Animal feedlot, Gun Powder plant, Food and Beverage- Dairy Products, Orange Juice factory, Wineries, Cookie factory, Vegetable processing plant, Meat packing, Barbecue Restaurant, Aquaculture, Ornamental Ponds with algae , CAFO, Nursing homes, Military, Campgrounds, Universities, Regulatory agencies, River and Lake remediation

Lab Services:

Filamentous Identification Lab Service. One reason to identify filaments is to determine the filaments characteristics and then determine the type present. If the type is found out, a root cause can usually be associated with a particular filament. If the cause is known, then a correction can be made to alleviate problems. Chlorination is only a quick fix. Without process changes, filaments will grow back after chlorination. Wastewater Biomass Analyses and Cooling Tower Analyses also available

Training Materials:

Training is an integral part of any job. Not everyone is at the same level of training. Many people want beginning concepts and basics. Some need technical information or troubleshooting. Some want equipment, technology or process information. We have developed a full set of Basic training, Advanced training, Filamentous Identification the Easy Way as well as custom training CD's Manuals. We also provide hands-on training classes and soon will have an Online "E-University".

Audits and Consulting:

At Environmental Leverage® Inc., we have a team of experienced individuals who come into your plant with a fresh pair of eyes. The system is checked from influent to effluent. System optimization, equipment efficiency and operational excellence are key components explored. Key Benefits Equipment efficiency Total Cost of Operation reductions Reliability and safety An onsite audit is conducted to examine system parameters, process controls, and current monitor and control procedures. A physical walk-through is conducted, process flow diagrams are examined, previous design criteria are examined and current standard operating procedures are evaluated along with data logs.

|

Troubleshooting-DigestersLatest News!

What's New!

We have just added "Virtual Audits" to our capabilities. Check out our new Services. We are in the process of developing new courses for our ""Online E-University" in order to meet the needs of our global customers that cannot travel to our public classes.Visit our new website www.WastewaterElearning.com/Elearning

Digesters- How well does yours run?

Lets take a look at a few types of digesters and some things we have

noted that can cause problems to these digestors.

One thing to note with anaerobic digesters if you are a municipal facility and blend secondary sludge along with primary solids and grease in your digester. If you have Nocardia in your secondary, and you feed large amounts of grease to the digester off your primary, you can cause foaming in the digester. Nocardia can grow in there if the conditions are right and this can cause problems with the system.

Here is one thing that might help your digester run better. Many times a plant physically removes grease in the primary, and then shoots themselves in the foot by placing all those grease solids back into the digester. If you already have mechanically scraped them off the surface and have the ability to landfill them as opposed to feeding them to the digester, change your options. Get them out of the system. Anytime you can physically lower the loading, the better. Get it out of the system. The amount of BOD in a 5 gallon pail of grease is incredible!

Many plants do not think of this because they really have not measured a small amount of grease, they measure the influent water, where most of the grease is not in high concentration and then assume that is the loading on the system. Here is a simple test, take a small amount of grease and send it off to your lab for BOD analyses! You might be surprised at how much you really have! This will change the amount of nutrients and trace minerals you might need to add to your digestor also! We had a few customers run these tests- COD ran anywhere from 1-4 million BOD for .1 gram of grease!

They run their aeration basins perfectly, watch the clarifiers, and then cause serious problems with their entire system because they do not control the digestor. They think of them as storage space prior to dewatering.

The only difference between the aeration basin and the digester in reality to the bacteria is that you are not supposed to be feeding them as much. Oh wait a minute, that's right you just fed them all that grease and solids which are basically food from the primary! Hmm, did you check your nutrients? Are there enough for all that loading? One thing you can do if you are short, is to put the supernatant return from the dewatering which will be high in nutrients back into the system if needed. Usually nutrients are not a problem in a digestor though if you have everything in balance because when you starve them, some of them die off and re-release the N and P back into the system. The only thing that can upset this balance is if you feed the digestor a ton of grease from the primary and in reality are not starving the system. Go check what the balance is if you batch load off your primary!

This also may be a reason why your digester is not reducing the volatile solids very much. You do not really have a digester if the food loading from the grease is high.

Digesters still need the basic "Critical 5"

components in the same range as the aeration basin if you really intend

to reduce solids and save on your

Ok, so back to pH and D.O. control. Some plants try to turn off the air in the digestor for numerous reasons. One reason is to decant the solids so they can be dewatered and return some of the supernatant back to the front of the plant. While this is necessary, the amount of time you decant is critical.

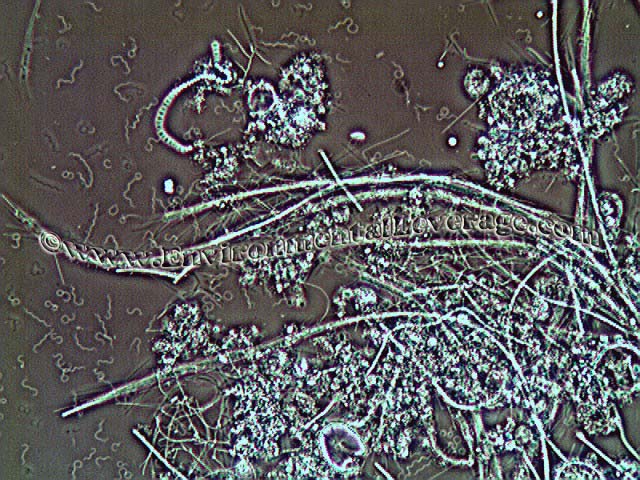

The longer you have the air off, the lower the D.O. goes. This impacts numerous things. It can turn the system septic and cause filamentous bacteria to grow in the digestor. This makes it harder and harder to decant and dewater. Also, the septic supernatant goes back to the front of the plant, places more demands on the oxygen in the aeration basin and can lower available DO to the bacteria that need it for growth. The septic water can also cause the growth of filaments in the aeration basin, cause more settling problems in the clarifier and digestor, which makes you leave the air off longer and longer and the cycle continues and conditions worsen. This is a bad cycle that needs to be broken.

How do you break this cycle? Short term, you can hit the system with chlorine and use polymers to settle out the filaments. Long term, change the process, do not turn the air off as long, increase pH, and /or D.O. or whatever of the Critical 5 parameters you have out of control and start running the system optimally! You would be surprised at how small changes can impact the system significantly!

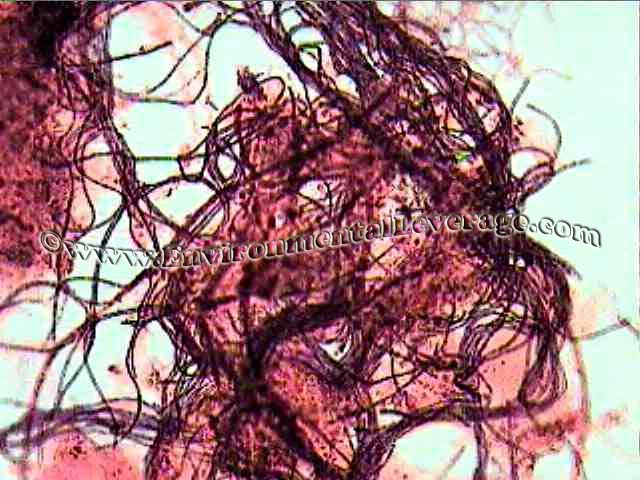

Have you ever pulled a sample and looked under the microscope at your digestor sample? Here is how we finally were able to solve the problem at two different plants- they both had tons of filaments and we could not get rid of the problems. No wonder, they were constantly reseeding the front of the system with filaments, depleting all the D.O., using large amounts of polymer in dewatering and hauling off more solids than necessary. Floating solids on the clarifier were a problem, foaming in the system was present and dewatering was hard. Decanting in the digestors was next to impossible. It's amazing though with just minor changes to a few areas in the process, how completely different the system could be!

This and Nocardia caused the solids in the clarifier to float. This was a simple fix, adjust the pH chemically and most of the problems would go away. Fungi loves to grow in a low pH and can easily be controlled by commodity chemicals simply! Results-more room would be available in the digestor, WAS could be increased off the clarifier, less filaments would grow and less solids to dewater! Simple fix for just pH adjustment. The amount of savings on solids handling, hauling, aeration and electricity would easily outweigh the additional cost of pH control. We told them to check with some of the local industries. Many times, they have spent caustic that they need to get rid of. This would be an easy way to solve issues for both plants! This plant also put in new screening and is now running wonderfully!

Here is plant B- They sometimes turned off the air for 1-2 days in the aerobic digester because they could not get the solids to decant enough for dewatering. What they created was a mess instead that slowly got worse!

Imaging trying to decant this or dewater this. It would be more like a sponge! Our solution to them, hit the system with chlorine for a small amount of time, used a small bit of polymer in the actual digestor to get it to settle, dewatered heavy for a few days, and finally break the cycle. Increase air in the digestor and check the pH. They now keep the air on and decant for only 1-2 hours at a time, and no problems in almost a year! The system is running smoothly.

Have you ever seen these in your aeration basin or digester? These are spirillum, they look like little cork screws and they wiggle around. Blow them up to higher power. They should be an instant eye opener to you that your system is septic. They grow in low DO or septic conditions. Get out your microscope? Check your system more often!! Remember, all the pieces are interconnected. One small change on a piece of equipment can sometimes make a significant impact on another piece in the system!

Here is a septic digester with scum floating on the surface. Here you can see gassing in this digester indicating septicity

Here are the "Critical 5 plus one" again as a reminder- Go check your digesters today!!! There are 5 critical measurements that should be monitored and controlled to effectively run a biological treatment plant efficiently; Temperature, DO, Ammonia, Ortho-phosphate and pH.

Acceptable Environmental Parameters for Biological Activity: There are 5 critical measurements that should be monitored and controlled to effectively run a biological treatment plant efficiently; Temperature, Dissolved Oxygen, Ammonia, Ortho-phosphate and pH.

PARAMETER

ACCEPTABLE

OPTIMUM

Alkalinity is the Plus one factor. This is critical for nitrifiers and for anaerobic digestors. See our training materials on anaerobic facilities and our nitrification training and troubleshooting tips.

Algae and mold on side walls of digester

Solids and debris build-up in the bottom of digesters. These indicate screening is not working. These solids can turn septic can cause issues in your digester.

Foaming in a digester can indicate an overload of grease in a municipality or food plant from the primaries or filamentous bacteria such as Nocardia.

Call Environmental Leverage Inc. today for a walk through of your plant to see the options you have for optimization of your system! You might be surprised at how little changes make a big impact!

Back to Troubleshooting tips and Newsletters

|

The

biggest thing that many plants need to improve with aerobic digesters is pH

control and D.O. levels.

The

biggest thing that many plants need to improve with aerobic digesters is pH

control and D.O. levels. We

have worked with numerous plants that had this type of cycle in their

systems. Low pH and not enough D.O. to start with, and then turning off the

air too long during the decant cycle.

We

have worked with numerous plants that had this type of cycle in their

systems. Low pH and not enough D.O. to start with, and then turning off the

air too long during the decant cycle.